Two Weeks of Focused Trainining on

IPS/ILS, Reliability, CM & Systems Engineering

IPS: Integrated Product Support

ILS: Integrated Logistics Support

PSA: Product Support Analysis

CM: Configuration Management

Two weeks of ONLINE and FACE-to-FACE (F2F) training brought to you by Quality Vertex Integrated Systems Engineering (QVISE) and GDS Engineering R&D, Inc. Six (6) instructors proficient in their areas of expertise provide this training, and Dr Ismail Cicek is the lead instructor for all sections.

Your Product, Our Support!

Always Evolving!

| Content | Duration (days) |

|---|---|

| Systems Engineering | 2.5 |

| Requirements Development and Management Engineering | 0.5 |

| Configurations Management | 1.5 |

| Risk Management | 0.5 |

| Integrated Product Support (IPS) & Integrated Logistics Support (ILS) | 2.5 |

| Test and Evaluation | 0.5 |

| Reliability Engineering | 1.5 |

| Environmental Stress Screening | 0.5 |

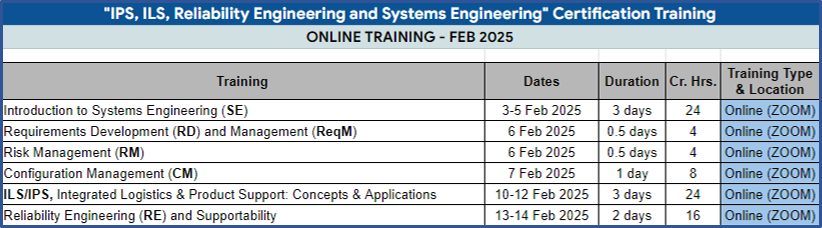

Schedule for Online Training (Feb 2025, Two Weeks):

You can register for all sections for a complete training certificate or only for interested modules. Individuals attending one section will receive a certificate of attendance for that specific module.

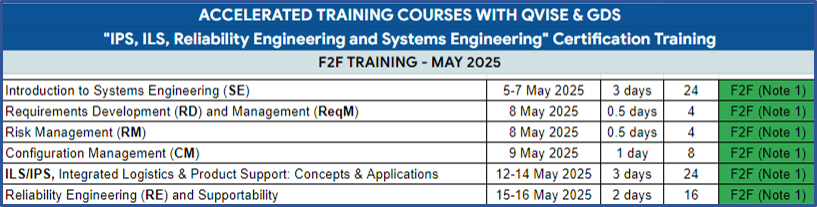

Schedule for Face-to-Face Training (May 2025, To Weeks | Tuzla, Istanbul):

Note 1: Face to Face training will occur in a classroom at Istanbul Technical University (ITU), Maritime Faculty, Tuzla Campus, Istanbul – Marine Equipment Test Center (METC).

The lead instructor, Dr Ismail Cicek, has the following relevant background:

- He has 20 years of experience as a US Department of Defense Projects and Programs systems engineer, for a total of over 30 years in the area.

- He was the Chief Engineer at the Certification Laboratories, US Air Force.

- He established a Test Center at Istanbul Technical University: Marine Equipment Test Center (METC).

- He is the Main Instructor for MIL-STD-810, RTCA-DO-160, Systems Engr., MIL-STD-461, and similar courses. He has provided training to over 1,000 individuals and over 120 organizations. He has also provided consultancy and engineering services to many organizations on environmental testing, equipment certification, and reliability testing.

We are teamed up with

Quality Vertex Integrated Systems Engineering (QVISE)

to provide the best training course on

IPS, ILS, Reliability Engineering,

Configurations Management and Systems Engineering.

We offer specialized training programs to equip professionals with the essential knowledge and skills to sustain complex systems and platforms. Our training courses are offered in the complex domains of:

- Integrated Logistics Support (ILS) / Integrated Product Support (IPS)

- Reliability Engineering

- Test & Evaluation

- Systems Engineering

- Configuration Management (CM)

Our training programs are expertly designed and customizable to cater to the industry’s evolving needs for providing practical learning experiences.

TRAINING ON

INTEGRATED LOGISTICS SUPPORT (ILS)

&

INTEGRATED PRODUCT SUPPORT (IPS)

Why You should choose “Us” for your ILS and IPS Training?

- We offer ILS / IPS training designed to empower professionals to enhance product supportability and sustainment.

- We collaborate with international partners, allowing the trainees to benefit from a diverse range of industry scenarios and best practices in ILS / IPS.

- Trainees can interact with instructors with well-regarded training experience, potentially including those who have delivered training to prestigious organizations.

- By choosing us, you gain the tools and expertise to improve supportability, reduce overall product life cycle cost, and enhance product availability.

Pre-Requisites

- Minimum 3 years of industry experience (Preferably Maintenance Oriented)

- Bachelor’s degree in electrical / Electronics / Mechanical / Mechatronics Engineering

- Integrated Logistics Support Basics

- Understanding of electronic equipment and components – for Electronics Engineers

- Knowledge of common mechanical equipment & components – for Mechanical Engineers

- Possess strong analytical skills

Testimonials

“The course content was incredibly relevant to my daily work. The tailored approach allowed me to apply the learned concepts to my current projects directly.” – IPS Team Member (Module – 2)

“Their deep knowledge of the subject matter was evident in their clear and engaging delivery. I felt encouraged to participate and ask questions, which greatly enhanced my learning experience. The practical and scenario-oriented examples brought the training to life and made the concepts easier to grasp.” – In-Service Team Member (Module – 3)

“The comprehensive coverage of LORA principles and methodologies has provided me with the tools to optimize maintenance strategies and make informed decisions in my role as an IPS specialist.”– IPS Team Member (Module – 6)

ILS / IPS Course Program Details

- We offer a comprehensive ILS / IPS certification program designed to equip professionals with the knowledge and skills necessary for effective product life cycle management.

- The program is structured into nine (9) distinct modules designed to provide a solid foundation in ILS / IPS.

- Our curriculum is carefully designed to align with Military standards and best practices, ensuring that participants gain a deep understanding of ILS / IPS principles, processes, and implementation techniques.

- Upon successful completion of the program, learners will demonstrate a basic level expertise of ILS / IPS concepts & strategies.

Course Module Distribution

CONTENTS OF ILS/IPS TRAINING

- Module 1: Introduction to ILS / IPS, Reliability and Supportability Engineering

- Module 2: Product Support Analysis (PSA) Insight

- Module 3: Life Cycle Costing (LCC), Availability and Maintainability Analysis

- Module 4: Logistics Product Data (LPD)

- Module 5: Synergizing Maintenance Strategies

- Module 6: Level Of Repair Analysis (LORA), Producibility and Supportability Assessment

- Module 7: Supply Support, Provision & Obsolescence Management

- Module 8: Packaging, Handling, Storage & Transport (PHS&T)

- Module 9: ILS / IPS Contact Management

IN-CLASS WORKSHOPS

MODULE 1 INTRODUCTION TO ILS / IPS, RELIABILITY & SUPPORTABILITY ENGINEERING

Objectives:

- Acquire a comprehensive understanding of IPS elements, their purpose, benefits, and applications

- Identify key IPS deliverables across the acquisition life cycle phases

- Develop awareness of PSA (Product Support Analysis), LPD (Logistics Product Data) and grasp the fundamentals of ILS Plan (ILSP) development

- Understand the fundamental concepts and principles of Reliability Engineering

- Identify key tasks and activities associated with Reliability program

- Understand the integration and processes of ILS and Reliability within the system life cycle phases

Course Outline:

- Introduction to Reliability Engineering

a) Brief History

b) What is Reliability Engineering

c) Overview of Reliability Program Tasks as per MIL-STD-785B - Reliability Modeling

a) Functional Block Diagram (FBD)

b) Reliability Block Diagram (RBD) - Reliability Prediction

a) Parts Stress Analysis

b)Live Demo on FALCON software - Mean Time Between Failure (MTBF) Calculation Techniques

a)In-Service MTBF Calculation - Introduction to ILS / IPS

a) History and transition from ILS to IPS

b) Elements of IPS - PSA (Product Support Analysis)

a) Transition from LSA to PSA

b) PSA Process in different Life cycle Phases

c) PSA Tailoring + Live Demo on FALCON - FMECA (Failure Modes, Effects & Criticality Analysis)

a) Qualitative FMECA

b) Quantitative FMECA

c) Live Demo on FALCON - RCM (Reliability Centered Maintenance)

a) RCM as a Failure Management Process

b) RCM Decision Logic Tree + Workshop - Condition Based Maintenance (CBM)

a) CBM & CBM +

b) CBM Techniques

c) CBM + and US DoD Acquisition Life cycle - FRACAS (Failure Reporting, Analysis & Corrective Action System)

a) FRACAS Concept

b) FRACAS Process

c) FRACAS vs FMEA / FMECA

d) Workshop

e) Live Demo on FALCON - MTA (Maintenance Task Analysis)

a) MTA as Activity 12 of PSA

b) Live Demo on FALCON - LORA (Level Of Repair Analysis)

a) LORA Process

b) Factors Affecting LORA - Availability

a) Achieved & Inherent Availability

b) Operational Availability

c) Workshop + Activity - LCCA (Life Cycle Cost Analysis)

a) Costing Categories

b)Life Cycle Cost Methods

c) Live Demo on FALCON - IETM (Interactive Electronic Technical Manual)

Management, Authoring and Publishing using live demo on FALCON - Obsolescence Management (OM)

a) Analysis & Assessment

b)Mitigation & Resolution - CM (Configuration Management)

a) CM Functions

b) Configuration Change Management

c) Live Demo of FALCON for CM - LSAR / LPD (Logistics Support Analysis Record / Logistics Product Data)

a) LPD Entities in Life Cycle Phases

b) Important LPD DEDs in LPD

c) Live Demo on FALCON - Spare Support

a) Spare Allowance Computation

b) Spare Optimization & Procurement Decisions

c) Live Demo on FALCON - MRO (Maintenance Repair Overhaul) and Shopfloor Management

a) Maintenance Planning

b) Maintenance Data Collection

c) Tools & Techniques for Maintenance Management

d) Live Demo on FALCON

MODULE 2 PRODUCT SUPPORT ANALYSIS (PSA) INSIGHT

Objectives:

- Comparison of Product Support Analysis (MIL-HDBK-502A, TA-STD-0017) with Logistics Support Analysis (MIL-STD-1388-1A) & its transition

- Acquire knowledge on Product Support Strategy and PSA reviews

- Learn how to develop PSA Plan and Support Plan

- Understand how to analyze cost, readiness and supportability drivers and formulate supportability objectives

- Understand PSA outcomes, how to conduct trade-off analyses, and assess supportability risk

- Master development PSA activity flows, identifying responsible parties and aligning deliverables

- Tailor PSA program and process to align with specific program requirements

Course Outline:

- LSA and PSA comparison and transition

- PSA Activities & sub-activities

a) Activity flow in Life cycle Phases

b) Activity 1 to 5 (+ Workshop)

c) Identify Cost Drivers

d) Analyze Risk for each activity

e) Activity 6 to 9 (+ Workshop)

f) Develop Support Plan

g) Activity 10 to 12 (+ Workshop)

h) Activity 13 to 17 - PSA Activities in a Product life cycle flow with Responsibles as Government & Contractor

- Tailoring of PSA Activities

a) Tailoring Factors & Considerations

b) Tailoring Case Study + Workshop

MODULE 3 LIFE CYCLE COSTING (LCC) AND A&M ANALYSIS

Objectives:

- Understand the concept of life cycle costing, its objectives, and cost estimation categories

- Learn various life cycle costing methods & models for decision-making

- Understand a simple life cycle cost model for comprehensive cost analysis

- Analyze the impact of mission profiles, cost-benefit trade-offs, and delays on operational availability (AO)

- Understand the concept of Administrative and Logistics Delay Time (ALDT) and its impact on AO

- Grasp the significance of maintainability in complex systems and impact on system performance

- Learn how to apply Maintainability prediction using MIL-HDBK-472 Notice 1 Procedure V, conduct maintainability reviews to identify and address potential issues

- Understand the role of Testability in Maintainability including its metrics and relation with FMEA

Course Outline:

- Introduction to Life Cycle Costing

a) Costing Overview and Categories

i. Life Cycle Cost (LCC)

ii. Total Ownership Cost (TOC)

iii. Whole Life Cost (WLC)

b) Life cycle Cost Objective and Needs

c) Life cycle Cost Estimate scoping

d) Life cycle Costing Methods

e) Life cycle Costing Models

f) Types of Cost Estimation

g) Limitations of Life cycle Costing - Life Cycle Cost Analysis

a) Life cycle cost Element Structure

b) Escalation / Inflation and Discount Factor (+ workshop) - Life cycle Cost (LCC) Model

a) LCC Model Objectives

b) Sample LCC Model

c) LCC Inputs, schedules, algorithms & outputs

d)Examples & Numericals - Maintainability Engineering

a) Objectives

b) Maintainability Concepts and Responsibilities

c) Maintainability Standards & key tasks - Maintainability Prediction + workshop

a) Maintainability Prediction & its application - Maintainability Reviews

a) Reviews & Tradeoff Techniques - Factors Affecting Maintainability

- Maintenance Classification, Process and Categories

- Testability Engineering + workshop

a) Important Terms & Definitions

b) BIT, BITE and ATE

c) Testability Requirements

d) Fault Detection

e) Fault Isolation

f) Ambiguity Group

g) False Alarm Rate - Overview of Availability and Readiness

a) Elements of Availability

b) Availability Prediction - Operational Availability Objectives

a) Analysis rationale and checklist - Operational Availability, Mission Profile and Cost Benefits Tradeoff

a) Mission Profile + workshop

b) AO Cost benefit Tradeoff analysis - Effects on AO

a) Administrative and Logistics Delay Time (ALDT) + workshop

b) Numericals and Activity

c) Operational Effectiveness and its Factors

d) Steady State, Instantaneous Operational Availability and Markov Principle

MODULE 4 LOGISTICS PRODUCT DATA (LPD)

Objectives:

- Understand the use and application of LPD Standards including the past MIL-STD-1388-2B and the new standards SAE GEIA-STD-0007-B, SAE TA-HB-0007-1 & SAE GEIA-HB-0007

- Effective utilization of LPD data elements to make informed decisions about when and how to use them

- Tailor LPD implementation to suit the specific needs of the customer, ensuring relevance and efficiency

- Learn how to apply and develop LPD data effectively to streamline maintenance, repair, and support processes as part of IPS package development

- Enable to develop the basic Product Support Package as an outcome of all the PSA activities

Course Outline:

- LSAR & LPD Comparison and Transition

a) LSAR & LPD Overview.

b) LSAR and LPD Comparison and handbooks - LPD Data Entities

a) List of LPD Entities and their relationship with PSA Activities in Life cycle Phases - Entities X: Cross-functional Requirements

a) LCN (LSA Control Number)

b) Types of LCN Assignment

i. Classical

ii. Modified Classical

iii. Sequential

c) LCN Structure & LCN Indenture

d) ALC (Alternate LCN)

e) LCN Type

f) System / End Item Identifier

g) Usable on Code (UOC)

h) LCN to System / End Item UOC mapping

i) LCN to Serial Number UOC mapping

j) CAGE (Commercial & Government Entity)

k) Document IDs and Technical Manual code - Entities A: Operation and maintenance requirement

a) Wartime vs Peacetime

b) Mission Profile

c) Annual Operating Requirements

d) Technical VS Operational Failure

e) RAM Requirements - Entities B: RAM, FMECA and Maintainability analysis

a) BIT (Built-In Test) and its characteristics

b) Ambiguity Groups

c) RAM Characteristics Measured VS Predicted VS Allocated VS Comparative

d) FMECA

e) Failure Mode Ratio (α)

f) EFM-MTBF (Engineering Failure Mode – Mean Time Between Failure)

g) Failure Effect Probability (β)

h) SHSC (Safety Hazard Severity Code)

i) Failure Mode & RAM Item Criticality Number

j) RCM - Entities G: Personnel skill considerations

a) SSC (Skill Specialty Code) - Entities F: Facility considerations

a) Facility Category Code - Entities E: Support equipment and training material requirements

a) SE ICC (Support Equipment Item Category Code)

b) SERD (Support Equipment Recommendation Data) - Entities U: Unit under test requirements and justification

a) UUT (Unit Under Test)

b) CMRS (Calibration Measurement Requirement Summary)

c) OTP (Operational Test Program) Data - Entities J: Transportability engineering analysis

a) Transportation Indicator

b) Shipping Modes - Entities H: Packaging and provisioning requirement

a) NSN (NATO Stock Number)

b) Shelf Life & Action Code

c) Packaging Code

d) PLISN (Provisioning List Item Sequence Number)

e) Essentiality Code

f)SMR (Source, Maintenance & Recoverability)

g) ICC (Item Category Code)

h) MRR (Maintenance Replacement Rate)

j) Provisioning Serial Number UOC Mapping

k) Provisioning System / End Item UOC Mapping

l) Provisioning Design Change Data - Entities C: Task inventory, task analysis, personnel and support requirements

a) Task Code

b) Task Frequency

c) Element Indicator

d) Task / Subtask SE and Provisioned Item - LSAR Reports

a) LSAR Report Analysis

b) Relationship with IPS Elements

c) LSAR Reports Description (LSA-001) - Other LSAR reports Overview

MODULE 5 SYNERGIZING MAINTENANCE STRATEGIES

Objectives:

- Understand the evolution of maintenance practices and fundamental maintenance concepts.

- Differentiate between various maintenance approaches and their applications.

- Understand core principles of FMECA to identify potential failures and their impacts.

- Apply Reliability Centered Maintenance (RCM) methodology to develop effective maintenance strategies.

- Utilize various CBM & CBM+ technologies for fault detection and diagnosis.

- Learn to perform Maintenance Task Analysis.

- Understand the role of MRO in ensuring equipment reliability and safety.

- Understand the MRO activity workflow, including work order management and safety protocols.

Course Outline:

- Evolution of Maintenance

a)What is Maintenance?

b)Maintenance Functions - Maintenance Concept and levels

a) In Commercial Industries

b) In Defense / Military - Maintenance Philosophy

- Maintenance Strategy

- Maintenance Plan

- Types of Maintenances

a) Proactive

i. Scheduled

ii. Condition-Based

iii. Prognostics / Predictive

b) Reactive

i. Corrective / Unplanned - Failure Modes and Effects Analysis (FMEA) & Failure Modes, Effects & Criticality Analysis (FMECA)

a) Inputs of FMECA

b) Qualitative FMECA

i. Severity, Occurrence & Detectability

ii. Risk Priority Number (RPN)

c) Quantitative FMECA

i. Failure Mode Ratio (α)

ii. Failure Effect Probability (β)

d) Outputs of FMECA - Reliability Centered Maintenance (RCM)

a) RCM Analysis (RCMA)

b) RCM Process

c) Principles - RCM Decision Logic & Task Evaluation

a) Servicing Task

b) Lubrication Task

c) On Condition Task

d) Potential Failure (PF) Curve

e) Hard Time Task

f) Failure Finding Task

g) No PM – Run To Failure Task

h) Other Actions

i) Age Exploration & Plan - RCM Task Selection

a) Special Considerations

b) Prognostics Health Monitoring (PHM) - RCM Detailed Process as per NAVAIR 00-25-403

a) Case Studies

b) Workshop - Condition Based Maintenance CBM

a) Goals, Advantages & Disadvantages

b) Monitoring Techniques - CBM +

a) Evolution

b) Design and Process

c) Objectives & Metrics

d) Business and Technical Needs

e) CBM+ Acquisition Lifecycle - Maintenance Task Analysis (MTA)

a) Requirements

b) MTA & PSA (Product Support Analysis) Coordination

c) Overview of Activity 12 / Task 401 of PSA / LSA

d) MTA template and developing Task Analysis data

e) Workshop - FRACAS (Failure Reporting, Analysis & Corrective Action System)

a) FRACAS Concept

b) FRACAS Process

c) FRACAS vs FMEA / FMECA

d) Case Study + Workshop - Maintenance Planning

a) Objective

b) (MAC) Maintenance Allocation Chart

c) LSAR Reports for Maintenance Planning - MRO (Maintenance Repair Overhaul) Facility

a) Evolution

b) MRO in Military - MRO and Shopfloor Management

a) MRO & FRACAS

b) Work Order

c) Job Card

d) Automated Tools

MODULE 6 LEVEL OF REPAIR ANALYSIS (LORA), PRODUCIBILITY AND SUPPORTABILITY ASSESSMENT

Objectives:

- Understand LORA process and its management

- Learn to apply decision-making logic to LORA, considering project constraints, Economic LORA through an analytical model & calculate most cost-effective maintenance strategy.

- Analyze LORA workflows and identify non-economic factors influencing repair decisions.

- Perform sensitivity analyses to evaluate LORA outcomes under varying conditions.

- Understand concept of supportability and its role in product life cycle management.

- Distinguish between government and contractor supportability responsibilities.

- Conduct supportability analyses, including functional and physical assessments.

Course Outline:

- Introduction to LORA

a) Overview & Purpose

b) Types of LORA Evaluation

i.Economic LORA

ii.Non-Economic LORA

c) LORA Program - LORA Program & Process as per SAE AS 1390

a) Activity 1 – Program Strategy

b) Activity 2 – Program Planning

c) Activity 3 – Program Reviews

d) Activity 4 – Input Data Compilation

e) Activity 5 – Evaluation Performance, Assessment & Documentation

f) Activity 6 – Using Results - LORA Decision Logic

- LORA Tailoring

- LORA Analysis

a) Non-Economic LORA

b) Questions regarding Non-Economic LORA - Types of Economic LORA Model

- NAVSEA Economic LORA Model

a) Cost Threshold

b) System and Item Variables

c) Pre-requisite Calculations

d) Spares pipeline expansion

e) Base & Repair Calculation

f) Additional Support Resource calculation - Sensitivity Evaluation

a) Overview & Explanation

b) Logic and Examples - Producibility

a) Tools & Techniques - Establishing Producibility Infrastructure

a) Organize for Producibility

b) Risk Management

c) Employ Producibility Design Guidelines - Producibility during Conceptual & Detailed Design Phases

- Producibility Case Study + Workshop

- Supportability Assessment

- Supportability Engineering Process

a) Government & Contractor Process - Design Supportability Characteristics

a) Formal & Informal Assessment

b) Government & Contractor Assessment

c) Supportability Demonstration - Support Resource

- Support Infrastructure

- Supportability Objectives & Metrics + Workshop

a) Fault Detection Ratio (FDR)

b) Fault Isolation Rate (FIR)

c) False Alarm Rate (FAR)

d) Maintenance Burden

e) Materiel Availability (AM)

f) Repair Cycle Time (RCT)

g) Personnel Requirements

MODULE 7 SUPPLY SUPPORT, PROVISIONING & OBSOLESCENCE MANAGEMENT

Objectives:

- Understand the fundamentals of supply support and provisioning, including their role in product support.

- Develop provisioning strategies and technical documentation, including provisioning codes

- Analyze spare part requirements using various forecasting models and techniques.

- Utilize the FLSIP model for spare part forecasting and optimization.

- Apply statistical methods (e.g., Poisson distribution) for spare part demand analysis.

- Implement effective obsolescence management strategies to mitigate risks and ensure product support continuity.

- Analyze the impact of obsolescence on product support and develop mitigation plans.

Course Outline:

- Supply Support

a) Overview & Introduction

b) What is Provisioning?

c) Need for Provisioning

d) Objectives of Provisioning - Provisioning Process

- Provisioning Codes + Workshop

a) Reference Number (Part #)

b) NATO Stock Number (NSN)

c) Part Military Essentiality Code (PMEC)

d) Shelf Life

e) Source, Maintenance & Recoverability (SMR) Code

i. SMR Format

ii. Explanation & usage of SMR Codes

f) Allowance Parts List (APL)

g) Maintenance Replacement Rate (MRR)

h) Minimum Replacement Unit (MRU)

i) Provisioning List Item Sequence Number (PLISN)

j) Provisioning Contract Control Number (PCCN)

k) Production Lead Time (PLT)

l) Recommended minimum stock level - Provisioning Technical Document (PTD)

- Engineering Data for Provisioning

- Provisioning Screening and Submittal

- Provisioning reports from LSAR

- Spare Forecasting / Spare Support

a) Need for Spare Forecasting

b) Spare Forecasting

c) Spare Forecasting Techniques - Qualitative Approach

- Quantitative Approach

a) Sparing to Availability Model

b) Readiness Based Sparing (RBS) Approach

c) Vari-METRIC Approach - FLSIP (Fleet Logistics Support Improvement Program) Model

a) Overview & Types of FLSIP

b) Case Study

c) FLSIP .5Plus & FLSIP .25

d) Workshop - Poisson Distribution

a) Overview

b) Case Study

c) Workshop - Warehouse & Stocking

a) Overview

b) Management Function - Obsolescence

a) Reasons of Obsolescence

b) Types of Obsolescence

c) Product & Parts affected by Obsolescence - Obsolescence Management (OM)

a) Categorization of OM approaches

b) Reactive & Proactive Obsolescence Management - Proactive Obsolescence Management

a) Initial Obsolescence risk analysis

b) Product Obsolescence and aftersales - Strategic Obsolescence Management (OM)

a) Project Management principles in OM

b) Initiation Stage

c) Planning & Design Stage

d) Execution Stage

e) Monitoring and controlling stage - Forecasting Obsolescence

- Obsolescence Risk Assessment Process

a) Case Study

b) Workshop

MODULE 8 PACKAGING, HANDLING, STORAGE & TRANSPORT (PHS&T)

Objectives:

- Understand the concept and fundamentals of Packaging, Handling Storage & Transport (PHS&T) including their role in product support

- Learn the important information of relevant standards and technical pamphlets (TPAMs) relating for PHS&T

- Master the Military Packaging rational along with LSAR/LPD codes on methods of preservation, cleaning, and drying procedures along with the use of cushioning and dunnage (MIL-STD-2073-1E/4)

- Learn the proper handling & storage methods for various military items to ensure their safety and integrity during storage, transport, and operational use

- Learn the methods of better deployment and transportation for a product / system and its sectionalized item(s) (MIL-STD-1366E)

Course Outline:

- Packaging, Handling, Storage & Transport (PHS&T)

- PHS&T as IPS elements

- Overview & Introduction

- Definition & Description

- PHS&T Program management as per MIL-STD-1367

- PHS&T Management Procedure

- PHS&T Program Implementation

- PHS&T Tailoring

- Military Packaging as per MIL-STD-2073-1E/4

- Method of Preservation

- Cleaning & Drying Procedure

- Preservative Material

- Cushioning & Dunnage

- Cushioning Thickness

- Unit Container

- Other Packaging Codes

- Military Handling

- Types of Handling

- Military Handling Items

- Handling Techniques based on Environment

- Military Storage

- Types of Military Storage

- Storage Procedures

- Storage Techniques

- Storage Security

- Transportability

- Modes of Transport & their Limitations

- Transportability Approval

- Transportability Testing

- Dos and Don’ts in Transportability

- Lessons Learned

MODULE 9 ILS / IPS CONTRACTING MANAGEMENT

Objectives:

- Understand the critical role of contracts for ensuring the required level of product support

- Understand the basics of contracting relating to ILS / IPS and how to manage ILS / IPS contracts and their complexities

- Navigate the complexities of ILS / IPS contracting processes, including pre-award activities, oversight, and reporting for ILS / IPS and LSA tasks / PSA activities

- Learn the insights on an IPS/ ILS contract and handling it based on different cases

Course Outline:

- Introduction to Contract

- Types of Contracts

- Sections in a Contract

- Product Specification

- SOW (Statement of Work)

- Data List

- Terms & Conditions

- Relevant Government / Customer Documents

- The Contracting Process

- Contracting for ILS / IPS

- Sample Contract Format

- Proposal Preparation & Pricing

- Contract Management Issues & Risk Management

TRAINING ON

RELIABILITY ENGINEERING

- The Reliability Engineering Courses are focused to provide individuals with a complete run-down of all the basics of a Reliability Program, with a solid foundation.

- The program is structured into eight (8) distinct modules designed to be thorough yet concise.

- Our curriculum is carefully designed to align with Military standards and best practices, ensuring that participants gain a deep understanding of Reliability Engineering principles, processes, and implementation techniques.

- Upon successful completion of the program, learners will demonstrate a basic level expertise of Reliability Engineering concepts & strategies.

Why You should choose “QVISE-GDS” for your ILS Training?

- We offer exceptional Reliability Engineering training to empower professionals to enhance product performance and durability.

- Our expert instructors combine industry knowledge with practical experience to deliver comprehensive and engaging training programs.

- You benefit from our hands-on approach, real-world case studies, and tailored curriculum to meet your specific reliability objectives.

- By choosing QVISE, you gain the tools and expertise to optimize product reliability, reduce failures, and improve overall product life cycle performance.

Pre-Requisites

- Bachelor’s degree in electrical / Electronics / Mechanical / Mechatronics Engineering

- Minimum 3 year of industry experience is recommended

- Understanding of Technical Documentations i.e., P&ID, BOM and Process Flows

- Understanding of technical specifications

- Proficient in algebra, probability & statistics

- Well-versed in calculus (Integration)

Testimonials

“The trainer's extensive experience was invaluable. Their insights and sharing of examples from personal experience provided practical guidance that I can directly apply to my work. I'm confident that this training will significantly contribute to my professional growth.”

– Reliability Team Member (Module – 3)

"The practical examples and clear explanations of equations and notations were invaluable. This training has equipped me with the tools to confidently apply reliability concepts in my future projects.“ – Subject Matter Expert (Module – 4)

“Compared to previous reliability trainings, this course was exceptional. The content was more relevant, engaging, and practical.” – Reliability Team Member (Module – 4)

Reliability Engineering Course Details

- Module 1: Introduction to ILS/ IPS, Reliability & Supportability Engineering

- Module 2: Reliability Governance & Contractual Management

- Module 3: Reliability Program Reviews & Failure Review Board (FRB)

- Module 4: Reliability Modeling & Allocation

- Module 5: Reliability Prediction

- Module 6: Failure Modes, Effects & Criticality Analysis (FMECA) and Failure Reporting Analysis & Corrective Action System (FRACAS)

- Module 7: Reliability Growth (RGT) & Environmental Stress Screening (ESS)

- Module 8: Reliability Qualification & Production Reliability Acceptance Testing (RQT & PRAT)

Management, Authoring and Publishing using live demo on FALCON

MODULE 1 INTRODUCTION TO ILS / IPS, RELIABILITY & SUPPORTABILITY ENGINEERING

Objectives

- Acquire a comprehensive understanding of IPS elements, their purpose, benefits, and applications

- Identify key IPS deliverables across the acquisition life cycle phases

- Develop awareness of PSA (Product Support Analysis), and LPD (Logistics Product Data) and grasp the fundamentals of ILS Plan (ILSP) development.

- Understand the fundamental concepts and principles of Reliability Engineering

- Identify key tasks and activities associated with Reliability program

- Understand the integration and processes of ILS and Reliability within the system life cycle phases

Outline

- Introduction to ILS / IPS, Reliability and Supportability Engineering

- Brief History

- What is Reliability Engineering

- Overview of Reliability Program Tasks as per MIL-STD-785B

- Reliability Modeling

- Functional Block Diagram (FBD)

- Reliability Block Diagram (RBD)

- Reliability Prediction

- Parts Stress Analysis

- Live Demo on FALCON software

- Mean Time Between Failure (MTBF) Calculation Techniques

- In-Service MTBF Calculation

- Introduction to ILS / IPS

- History and transition from ILS to IPS

- Elements of IPS

- PSA (Product Support Analysis)

- Transition from LSA to PSA

- PSA Process in different Life cycle Phases

- PSA Tailoring + Live Demo on FALCON

- FMECA (Failure Modes, Effects & Criticality Analysis)

- Qualitative FMECA

- Quantitative FMECA

- Live Demo on FALCON

- RCM (Reliability Centered Maintenance)

- RCM as Failure Management Process

- RCM Decision Logic Tree + Workshop

- Condition Based Maintenance (CBM)

- CBM & CBM +

- CBM Techniques

- CBM + and US DoD Acquisition Life cycle

- FRACAS (Failure Reporting, Analysis & Corrective Action System)

- FRACAS Concept

- FRACAS Process

- FRACAS vs FMEA / FMECA

- Workshop

- Live Demo on FALCON

- MTA (Maintenance Task Analysis)

- MTA as Activity 12 of PSA

- Live Demo on FALCON

- LORA (Level Of Repair Analysis)

- LORA Process

- Factors Affecting LORA

- Availability

- Achieved & Inherent Availability

- Operational Availability

- Workshop + Activity

- 14.LCCA (Life Cycle Cost Analysis)

- Costing Categories

- Life Cycle Cost Methods

- Live Demo on FALCON

- IETM (Interactive Electronic Technical Manual)

- Management, Authoring and Publishing using live demo on FALCON

- Obsolescence Management (OM)

- Analysis & Assessment

- Mitigation & Resolution

- CM (Configuration Management)

- CM Functions

- Configuration Change Management

- Live Demo of FALCON for CM

- LSAR / LPD (Logistics Support Analysis Record / Logistics Product Data)

- LPD Entities in Life Cycle Phases

- Important LPD DEDs in LPD

- Live Demo on FALCON

- Spare Support

- Spare Allowance Computation

- b)Spare Optimization & Procurement Decisions

- c)Live Demo on FALCON

- MRO (Maintenance Repair Overhaul) and Shopfloor Management

- Maintenance Planning

- Maintenance Data Collection

- Tools & Techniques for Maintenance Management

- Live Demo on FALCON

MODULE 2 RELIABILITY GOVERNANCE

Objectives

- Master the identification and application of relevant reliability standards and reference materials

- Develop and implement effective reliability programs aligned with industry standards and guidelines

- Acquire proficiency in various reliability analysis methods and testing procedures

- Optimize reliability data collection and parts management processes

- Select appropriate reliability standards based on specific project requirements

- Compare and contrast different reliability standards in terms of their frameworks, recognition, emphasis, coverage, and applicability

Outline

- Reliability Governance

- Standardization, its Need and importance

- Governing Bodies for standards

- Reliability & Maintainability Categorization

- Reliability Program management (MIL-STD-785B)

- Features & Limitations

- Tasks in for Reliability Program

- Reliability Analysis Methods

- MIL-HDBK-217

- MIL-STD-756

- MIL-STD-1629

- MIL-STD-2155

- Reference Guides and Handbooks

- Overview & Purpose of Handbooks

- Applicable Handbooks

- DOD RAM Guide

- MIL-HDBK-454

- MIL-HDBK-338

- MIL-HDBK-338

- RAM (Reliability, Availability & Maintainability) Theory

- Reliability Specification, Allocation, Modeling & Prediction

- Reliability Engineering Design Guidelines

- Reliability Data Collection and Analysis, Demonstration & Growth

- Software Reliability

- Systems Reliability Engineering

- Production and Use (Deployment) R&M

- Maintainability Analysis

- Introduction

- Applicable & Recommended Documents

- Military STD / HDBK

- MIL-STD-721

- MIL-STD-470B

- MIL-HDBK-472(Notice 1)

- MIL-STD-471A

- MIL-STD-2165

- DoD-HDBK-791

- BS EN 50126-1

- Comparative Analysis

- Reliability Testing

- MIL-STD-781

- MIL-STD-810 – Overview

- MIL-STD-1635 – Overview

- MIL-STD-2074

- MIL-STD-2164 – Overview

- System Safety

- Introduction

- Applicable Standards

- MIL-STD-882E

- IEC 61508-1:2010

- Data collection and parts information

- Importance of Reliability Data

- MIL-STD-690

- MIL-STD-790

- MIL-STD-883

- MIL-STD-965

Live Demonstrations Led by the Instructor(s) using QVISe/FALCON

MODULE 3 RELIABILITY PROGRAM REVIEWS & FAILURE REVIEW BOARD

Objectives

- Understand the purpose and timing of program reviews, and their role in preventing project failures.

- Integrate reliability program management with overall project management principles.

- Align reliability engineering activities with program and project life cycle stages.

- Participate effectively in System Engineering Technical Reviews (SETRs) with a focus on reliability and maintainability (RAM) aspects.

- Identify reliability-related aspects within various SETR

- Apply Root Cause Analysis (RCA) techniques for failure investigation and prevention.

- Establish and conduct effective Failure Review Boards in accordance with industry best practices.

Course Outline

- Introduction to Reliability Program Reviews

- What is a Program Review

- Relation to Reliability Engineering and Reliability Program Review

- Why to conduct Reviews

- Project Monitoring & Evaluation

- Benefits of Reviews

- Review guidelines and processes

- Elements of Review

- Reliability and Systems Engineering

- What is Systems Engineering

- Relationship with Reliability Engineering

- Program / Project Lifecycle

- Systems Engineering Technical Reviews

- Case Study + Workshop on ASR

- Reliability Program Reviews Scheduling

- Preparation Activities

- Execution Activities

- Documentation

- Review consideration

- Types of Program Reviews

- Informal Reliability Reviews

- Formal Design / Program Reviews

- Systems Engineering Technical Reviews (SETRs) & Reliability

- Case Study + Workshop on PDR

- Software Review Categories

- Failure Review Board (FRB)

- Overview

- Importance of FRB

- c)Relationship between Reliability & Failure Reporting

- Root Cause Analysis Methods

- Overview

- Processes

- Techniques + Workshop

- Events & Causal Factors (ECF) charting

- The 5 ‘Whys’ method

- .Cause Tree method

- Why-Because Analysis (WBA) / Why-Because Graph (WBG)

- Fault Tree Analysis (FTA)

- Fishbone / Ishikawa

- KNOT Chart

- PARETO Analysis

- FRB Guidance

- Purpose and Scope

- FRB Requirements

- FRB Organization

- FRB Process

- FRB as Contractor & Customer

- Detailed Requirements

- FRB Capability Levels

MODULE 4 RELIABILITY ALLOCATION & MODELING

Objectives

- Master the concepts and applications of reliability modeling.

- Construct Failure Breakdown Diagrams (FBDs) and Reliability Block Diagrams (RBDs) to model system behavior.

- Calculate mission reliability and system reliability metrics.

- Utilize various probability distributions to model component and system behavior.

- Allocate system reliability to subsystems using appropriate methods.

- Employ advanced modeling techniques for complex system analysis.

- Analyze failure data and project it to appropriate probability distributions.

Course Outline

- Reliability Modeling

- Introduction

- Methodology

- Requirements

- Output Parameters

- Reliability Allocation

- Introduction

- Methodology

- Requirements

- Output Parameters

- Functional Block Diagram (FBD)

- Introduction

- Methodology

- Requirements

- Output Parameters + Workshop

- Reliability Block Diagram (RBD)

- Introduction

- Methodology

- Requirements

- Activity + Workshop

- Mission and Basic Reliability

- Introduction

- Requirements

- System Definition

- Calculation Procedure + Workshop

- Reliability Metrices + Workshop

- Reliability

- Failure Rate & Hazard Rate

- MTTF, MTBF & MRL

- Demonstrated Reliability

- RBD Models + Workshop

- Series System

- Parallel System

- K/N Redundant system

- Active redundancy or hot standby

- Passive redundancy or cold standby

- Warm standby

- Complex Series-Parallel System

- Failure Rate Relationship

- Probability 101

- Definition, formula & examples

- Rules of Probability + Workshop

- Joint Probability, conditional Probability

- Complement probability, dependent / independent probabilities

- Mutually exclusive

- Probability Functions

- Probability Density Function (PDF)

- Cumulative Density Function (CDF)

- Relationship between PDF & CDF

- Reliability Function

- Failure Rate Function

- MTTF Function

- Life Distributions

- Exponential + Workshop

- Weibull + Workshop

- Normal + Workshop

- Lognormal + Workshop

- Gamma

- Reliability Allocation Methods

- Equal Apportionment + Workshop

- ARINC + Workshop

- AGREE + Workshop

- Feasibility of Objectives (FOB) + Workshop

- Modified FOB + Workshop

- Modelling methods & Calculation

- Conventional Probability + Workshop

- Boolean Truth Table + Workshop

- Logic Diagram + Workshop

- Monte Carlos Simulation + Workshop

- Probability Plotting – Nonparametric (for in-service MTBF calculation of System)

- Overview & Model + Workshop

- Nongroup Data / Kimbal Estimator

- Group Data / Statistical Estimator

- Probability Plotting – Exponential Distribution

- Overview & Model

- Fitting of data on exponential distribution

- Computing system Reliability of a complex series-parallel combination system with different Life Distribution on each component

Management, Authoring and Publishing using live demo on FALCON

&

Examples with Live Demos & Workshops

MODULE 5 RELIABILITY PREDICTION

Objectives

- Integrate reliability prediction into various product life cycle phases.

- Distinguish between different types of reliability predictions based on design stages.

- Apply life testing techniques for reliability prediction and utilize Physics of Failure (PoF) models for reliability assessment.

- Leverage the MIL-HDBK-217F-N2, IEEE 1413 standard for reliability prediction evaluation.

- Apply NSWC methodologies for mechanical item reliability prediction.

- Utilize the NPRD database for reliability prediction and adjustment.

- Evaluate the effectiveness of different reliability prediction methods through case studies.

Module Outline

- Reliability Prediction

- Introduction

- Application and benefits

- Important considerations

- Core concepts required

- e)General Procedure

- Reliability Prediction in System Lifecycle

- Classification based on Design Phase

- Type I – Feasibility Prediction

- Type II – Preliminary Design Prediction

- Type III – Detailed Design Prediction

- Prediction Technique – Life Testing

- Overview & purpose

- Advantages & disadvantages

- Requirements & Procedure

- Workshop

- Prediction Technique – Physics of Failure (POF)

- Overview & POF models

- Advantages & Disadvantages

- Requirements and Procedure

- Workshop

- Prediction Technique – Empirical Method

- Similar Item Method

- Similar Circuit Method

- Active Element Method

- Parts Count Method

- Parts Stress Method

- 7.Comparison of Prediction Techniques

- IEEE 1413 Overview

- Assessment Criteria

- Comparison

- Parts Count Analysis using MIL-HDBK-217FN2

- Activity + Workshop

- Parts Stress Analysis using MIL-HDBK-217FN2 + Workshop

- Microcircuits

- Diodes

- Transistors

- Resistors

- Capacitors

- Reliability Prediction using NSWC

- Bearing

- Poppet Valve

- Seals (O-rings)

- Springs

- Reliability Prediction using NPRD

- Overview of NPRD sections (1 – 8)

- Workshop for failure rate estimation

- Other Failure Rate Prediction standards

- Bellcore / Telcordia

- RDF 2000

- IEC 62380

- PRISM

- Practical Demonstration

- 217PLUS

- China GJB/z 299C, FIDES, OREDA

- Case Study + Workshop

- Comparison of Reliability Prediction Methods

- Comparison of Reliability Prediction Handbooks

- The Merits and limitations of Reliability Predictions

- Predicted MTBFs to Field and Test Data

- Case Study: Plastic Parts in the US DoD

MODULE 6 FMECA & FRACAS

Objectives

- Learn FMEA and FMECA, in accordance with industry standards as per MIL-STD-1629A, IEC, TM 5-698-4, AIAG-VDA

- Construct FTA and ETA models to identify potential failure scenarios and their consequences.

- Integrate FTA, ETA, and FMEA for comprehensive risk assessment.

- Implement a robust Failure Reporting, Analysis, and Corrective Action System (FRACAS).

- Conduct effective Root Cause Analysis (RCA) to identify and eliminate failure root causes.

- Develop and implement a comprehensive parts management plan.

- Establish and manage a Reliability Critical Items List (RCIL).

Module Outline

- Introduction to FMEA / FMECA

- Need for FMEA / FMECA

- Terminologies

- Types of FMEA / FMECA

- Basic concepts

- FMEA / FMECA Detailed Process

- System Scope and planning

- Failure Modes, Effects & Criticality Analysis as per MIL-STD-1629A

- Compensating Provisions

- Documentation

- Workshop + Case Study

- IEC Process for FMEA

- Planning FMECA

- Performing FMECA

4. FMECA for C4ISR (TM 5-698-4)

a) FMEA methodology / steps

b) Criticality ranking for qualitative and quantitative

c) Representation of results of FMECA

5. Process FMEA as per AIAG-VDA

a) Scope Definition of PFMEA

b) Structure and Function Analysis

c) Failure and Risk Analysis

d) Examples + Workshop

6. Fault Tree Analysis (FTA)

a) Overview & Application

b) Classification & Key Concepts

c) Symbols and Procedure

d) Requirements & considerations

e) Qualitative & Quantitative

7. Event Tree Analysis (ETA)

a) Overview & Objectives

b) Key concepts

c) Limitations

d) Procedure

8. Combination of FTA with other techniques

a) Failure Modes and Effects Analysis (FMEA)

b) Event Tree Analysis (ETA)

c) Reliability Block Diagram (RBD)

9. FRACAS (Failure Reporting, Analysis & Corrective Action System)

a) Terminologies

b) Typical FRACAS Process

c) FRACAS vs FMECA

10. Root Cause Analysis (RCA)

a) Introduction to RCA

b) Types of problems solved during RCA

11. Data Collection

a) RAM Data

b) Data Categories

12. Parts Management

a) Introduction

b) Policy and Contract Management

c) Costs and Benefits

d) Parts Management Plan

e) Responsibilities and Tools

13. Reliability Critical Items List

a) Introduction

b) Purpose

c) FMECA as a driver

MODULE 7 RELIABILITY GROWTH & ENVIRONMENTAL STRESS SCREENING (ESS)

- Introduction to Reliability Testing

a) Overview and objectives

b) Key Concepts

c) Test Program

d) Test Data Types - Failure Categories and Types

a) Failure definition and classification

b) Relevant vs Non relevant failures

c) Types of Failures - Reliability Testing Classification

a) Classification paradigm

b) Management aspects of reliability tests

c) Reliability test classification workshop - Introduction to Reliability Growth Testing (RGT)

a) Overview

b) Terminologies

c) Reliability Growth and Management control process

d) Reliability Growth Planning, Tracking and Projection Concepts - Reliability Growth Curves Types

a) Idealized Growth curve

b) Planned Growth curve

c) Growth Tracking curve - DUANE Plot

a) Overview

b) Time Terminated Testing

c) Failure Terminated Testing

d) Grouped Data Testing - AMSAA Model (US Army Materiel Systems Analysis Activity)

a) Time Terminated Testing

b) Failure Terminated Testing - Environmental Test Conditions (MIL-STD-810)

a) Test Survey

b) Combined Stresses

c) Single Stress - Accelerated Testing

a) Overview, Purpose and Classification

b) Qualitative Accelerated Testing

c) Quantitative Accelerated Testing - Introduction to Environmental Stress Screening (ESS)

a) Overview & Purpose

b) Key Concepts

c) Application of ESS in Product Lifecycle

d) ESS environment types and factors - ESS Program Elements

a) Planning Guidelines

b) Implementation procedures guidelines

c) ESS monitoring and performance reports - ESS Detailed Procedure

a) Procedure A till F - Non-operating Reliability

a) Introduction

b) Terminologies

c) Examples and workshop - Assessing Non operating Reliability

a) RADC Method

b) MIL-HDBK-217 “ZERO Electrical Stress Approach”

c)“K” Factor Approach - Martin-Marietta Test Program

a) Introduction

b) Methodology and findings

c) Analysis and methods

d) Workshop - Test and Maintenance

a) Introduction

b) Types of Tests

c) Maintenance Approaches

MODULE 8 RELIABILITY QUALIFICATION & PRODUCTION RELIABILITY ACCEPTANCE TESTING (RQT & PRAT)

- Introduction to RQT (Reliability Qualification Testing)

a) Objectives & Key Concepts

b) Requirements for Qualification

c) RQT in Product Lifecycle

d) Quality Management System (QMS) and Reliability - Virtual Qualification

a) Overview and objectives

b) Important aspects of Reliability Qualification - Product Qualification

a) Process for product qualification

b) Qualification of electronic components

c) Reliability Tests for Qualification - Quality Assurance

a) Quality Assurance and Reliability

b) Quality Control and Reliability - Introduction to PRAT (Production Reliability Acceptance Testing)

a) Overview and Objectives

b) Key concepts

c) Methodology

d) Classification - MTBF Assurance Test

a) Overview

b) Model

c) Procedure

d) Example + Workshop - Sequential Test Plan

a) Overview and Purpose

b) Model

c) Test Plans

d) Examples and Workshop - Fixed Duration Test Plan

a) Overview, Purpose and classification

b) Model

c) Test Plan

d) MTBF Estimation

e) Examples and Workshop - All Equipment Test Plan

a) Overview & Purpose

b) Model

c) Test Plans

d) Example and Workshop - Sampling Methods for Acceptance of Product

a) Overview & Terminologies

b) Acceptance by Contractor-Proposed Provisions - Acceptance by Standard Sampling Tables

a) Attributes Sampling + Workshop

b) Variables Sampling + Workshop

c) Continuous Sampling + Workshop - Statistical Process Control (SPC)

a) Overview

b) Key Characteristics to Control

c) Rational for Subgroup Size - SPC Control Chart

a) Overview

b) Variable Control Charts

c) Attribute Control Charts

TRAINING ON

CONFIGURATION MANAGEMENT

(CM)

Why Choose QVISE for your CM Training?

- We deliver high-quality, cost-effective, and up-to-date Configuration Management (CM) training and certification programs.

- We aim to equip CM professionals with a comprehensive understanding of the CM landscape, from foundational principles to advanced implementation techniques.

- Unlike single-perspective approaches, QVISE training offers a holistic view of CM, enabling learners to grasp diverse implementation options that align with industry best practices.

- By combining in-depth knowledge with practical experience, our expert instructors empower you to excel in managing complex product life cycles and driving project success.

Our View on Industry Standards

- We firmly believe adherence to industry standards is crucial for effective Configuration Management (CM) implementation.

- Standards such as SAE EIA 649, ISO 10007, ISO 9001, CMMI, and ITIL provide a robust framework for establishing and maintaining configuration control.

- These carefully designed guidelines, developed by industry experts, offer invaluable insights and best practices for CM processes.

- By incorporating a thorough understanding of these standards into our training programs, QVISE equips professionals with knowledge and tools necessary to implement world-class CM systems.

Testimonials

“The course material was comprehensive and professionally designed, incorporating the latest advancements and terminologies in CM. The insights gained will undoubtedly be utilized for future projects.” – R&D Team Member (Module – 3)

“The course was tailored specifically to our organization’s needs and offered an exceptional learning experience. It will definitely improve the skills & capability of individuals.” – Subject Matter Expert (Module – 4)

“The training experience was highly satisfactory, particularly the practical demonstrations of the FALCON CM software and the group activities, which greatly improved our understanding.” – Production Facility In charge (Module – 4)

CM Course Program Details

- We offer a comprehensive CM certification program structured into four distinct modules designed to provide a solid foundation in Configuration Management based on a five-days course as a single package.

- Our curriculum is carefully designed to align with industry standards and best practices, ensuring that participants gain a deep understanding of CM principles, processes, and implementation techniques.

- Upon completing the program, learners will demonstrate a mastery of CM requirements, a comprehensive grasp of CM elements and functions, and proficiency in applying modern CM methodologies to achieve successful project outcomes.

CM Course Modules

- Module 1: CM Foundation

- Module 2: CM Identification

- Module 3: Configuration Change-Management

- Module 4: CM Implementation

Pre-Requisites

- No formal prerequisites are required to enroll in this certification program.

CONTENTS OF CM TRAINING

MODULE 1 CM FOUNDATIONS

This foundational course offers a comprehensive exploration of Configuration Management (CM) principles and practices. Participants will gain a thorough understanding of CM planning, identification, auditing, change control, and status accounting processes. The course emphasizes the critical role of CM within an organization and serves as the first module in our four-part certification program.

Objectives:

- Establish a fundamental comprehension of CM principles and contemporary methodologies.

- To outline roles and responsibilities within the CM framework.

- To analyze the evolution of CM and its impact on product life cycle management.

- To explore strategies for minimizing corrective actions and ensuring consistent product conformance.

Outline:

- Introduction to Configuration Management

- Target Audience for Configuration Management

- Evolution and Requirements of Configuration Management

- Interrelationship between Configuration Management and Quality

- Core Components of Configuration Management

- Configuration Management Terminology

- Life Cycle Concepts

- Document, Data, and Management

- Configuration Management and Information

- Cost Implications of Configuration Management

- Common Misconceptions about Configuration Management

- Challenges and Risks of Not Implementing Configuration Management

MODULE 2 CM IDENTIFICATION

This course delves into the practical application of configuration identification principles. Participants will acquire in-depth knowledge of baselining, structuring, naming, and numbering methodologies. This module, the second in our four-part certification series, provides essential skills for effectively managing configuration items throughout the product life cycle.

Objectives:

- To develop proficiency in creating and maintaining structured configuration information and baselines.

- To clearly define the product or system to be built, operated, and maintained throughout its life cycle.

Outline:

- Overview of Configuration Identification

- Identification Schemes: Numbering and Naming Conventions

- Product Structure: Part One

- Product Structure: Part Two

- Establishing Configuration Baselines

- Integration of Identification and Change Management

- Configuration Management Database

- Approaches to Configuration Identification

- Interface Management

- Re-identification Processes

- Traceability and Configuration Identification

- Configuration Status Accounting and Identification

3 CONFIGURATION CHANGE MANAGEMENT

This module provides an in-depth examination of industry best practices for managing configuration changes throughout the product life cycle. Participants will gain practical experience in implementing effective change management strategies. This module constitutes the third component of our four-part certification program.

Objectives:

- To develop a comprehensive understanding of change management principles, workflows, responsibilities, and decision-making processes.

- To master the implementation of efficient and effective change management procedures from initiation to completion.

- To acquire proficiency in handling non-conformances and resolving change-related bottlenecks.

Outline:

- Configuration Change Management Overview

- Change Proposal and Analysis

- Change Evaluation and Decision Making

- Change Control Boards and Authority

- Change Implementation and Verification

- Change Implementation and Effectivity

- Change Prioritization and Classification

- Challenges and Issues in Configuration Change Management

- Optimizing the Change Process

- Deviations, Waivers, and Variances

- Configuration Status Accounting and Change

- Change Process Metrics and Performance Evaluation

4) CM IMPLEMENTATION

This module focuses on the practical application of CM principles and processes within an organizational context. Participants will learn how to effectively implement and integrate CM strategies into existing workflows. This module concludes our four-part certification program, providing learners with the skills necessary to drive CM maturity.

Objectives:

- To acquire proficiency in implementing CM process improvements.

- To develop CM plans and conduct comprehensive CM assessments.

- To apply CM principles to diverse organizational environments and product life cycles.

- To evaluate and select appropriate CM automation tools.

Outline:

- Configuration Management Planning

- Configuration Management Verification and Audit

- Configuration Management Roles and Responsibilities

- Customer and Supplier Integration in Configuration Management

- Configuration Management of Commercial Off-the-Shelf (COTS) Items

- Lean Principles and Configuration Management

- Configuration Management Process Assessment

- Configuration Management Tool Capabilities

- Selecting and Implementing Configuration Management Tools

- Configuration Management Process Improvement

- Achieving Configuration Management Success

- Course Review and Conclusion

TRAINING ON

SYSTEMS ENGINEERING

(SE)

Why Choose QVISE for your CM Training?

- We offer comprehensive Systems Engineering training to equip professionals with the skills and knowledge necessary to excel in complex project development and management.

- Our expert instructors combine in-depth industry experience with academic rigor to deliver engaging and practical training programs.

- Benefit from our hands-on approach, real-world case studies, and tailored curriculum designed to meet your specific needs.

- By choosing our training, you gain the competitive edge to optimize system design and processes, improve project efficiency, and drive successful outcomes.

Pre-Requisites

- Minimum 3 years of industry experience (Preferably Maintenance Oriented)

- Management Experience of at least 2 years (Preferred)

- Bachelor’s degree in electrical / Electronics / Mechanical / Mechatronics Engineering

- Integrated Logistics Support Basics

- Understanding of electronic equipment and components – for Electronics Engineers

- Knowledge of common mechanical equipment & components – for Mechanical Engineers

- Possess strong analytical skills

- Good understanding of mathematics

Testimonials

“For our recent project being carried out this course / training will be very beneficial.”

– SE Team Member (Module – 3)

“The course will influence my future work and the real case studies were the best part, where I could relate my past experiences and learn from the slight errors we had been making.” – SE Team lead (Module – 4)

“The Workshops have helped greatly in understanding the flow of real activities specially the technical processes to put into some practical use” – SE Team Member (Module – 4)

CM Course Program Details

- We offer a comprehensive SE training program designed to equip professionals with the essential skills and knowledge to master complex systems development and integration.

- This course covers the complete lifecycle of systems and products, from concept to delivery, ensuring participants gain a deep understanding of both technical processes and management practices.

- Our experienced instructors, deliver a dynamic learning experience through real-world case studies, hands-on exercises

- By choosing our training, you will gain the expertise needed to streamline your systems engineering processes, enhance project outcomes, and drive innovation within your organization.

CM Course Modules

- Module 1: Introduction To Systems Engineering

- Module 2: The System/ Product Life cycle

- Module 3: Technical Processes

- Module 4: Technical Management Processes

- Module 5: Technical Reviews

- Module 6: Practical Systems Engineering and Tailoring

CONTENTS OF SYSTEMS ENGINEERING (SE) TRAINING

1) INTRODUCTION TO SYSTEMS ENGINEERING (SE)

Objectives:

- Define Systems Engineering and its role in product development.

- Explain the key principles and concepts of Systems Engineering.

- Identify the core processes and activities involved in Systems Engineering.

- Understand the relationship between Systems Engineering and other engineering disciplines.

- Recognize the benefits of applying Systems Engineering principles to project success.

Course Outline:

- Defining what is a System

- Understanding types of Systems and related concepts

- Purpose of Systems Engineering and its importance

- Identifying stakeholders & users of a system

- General activities of a system

- Documentation in Systems Engineering

- Impact of systems engineering on an organization

- History of Systems Engineering & its evolution over the years

- Understanding roles & responsibilities of a Systems Engineer

2) THE SYSTEM / PRODUCT LIFE CYCLE

Objectives:

- Understand the different types of system/ product life cycles for military and commercial use.

- Describe the stages of the system/product life cycle and their interdependencies.

- Explain the key activities and deliverables associated with each life cycle stage.

- Understand the role of Systems Engineering in supporting the life cycle process.

- Identify potential risks and challenges at different stages of the life cycle.

Course Outline:

- An overview of the System/ Product Life cycle

- Life cycle Concepts & Approach

- Understanding the background of System/ Product Life cycles

- Exploring the different types of System/ Product Life cycles

- Planning of a System/ Product Life cycle

- The Concept Stage in a System/ Product Life cycle

- The Development Stage in a System/ Product Life cycle

- The Production Stage in a System/ Product Life cycle

- The Utilization/ Fielding Stage in a System/ Product Life cycle

- The Support Stage in a System/ Product Life cycle

- The Retirement/ Disposal Stage in a System/ Product Life cycle

3) SE TECHNICAL PROCESSES

Objectives:

- Explore the various technical processes involved in Systems Engineering.

- Identify the key stakeholders of technical processes.

- Understand the purpose and objectives of each technical process.

- Identify the key inputs, outputs, and activities associated with each process.

- Address common challenges and best practices for effective technical process implementation.

Course Outline:

- Overview of the Technical Processes in a System/ Product Life cycle

- Technical Processes in different standards/ guidebooks

- Business & Mission Analysis Process

- Requirements Analysis Process

- Stakeholder Needs & Requirements Definition Process

- System Architecture Design Process and System Analysis Process

- Implementation Process

- Integration Process

- Transition Process

- Verification Process

- Validation Process

- Operation, Maintenance & Disposal Process

4) SE TECHNICAL MANAGEMENT PROCESSES

Objectives:

- Explore the technical management processes involved in Systems Engineering.

- Identify the key stakeholders of technical management processes.

- Understand the purpose and objectives of each technical management process.

- Identify the key inputs, outputs, and activities associated with each process.

- Address common challenges and best practices for effective technical management.

Course Outline:

- Overview of the Technical Management Processes in a System/ Product Life cycle

- Technical Management Processes in different standards/ guidebooks

- Technical Planning Process

- Project Assessment & Control Process

- Decision Analysis Process

- Technical Assessment Process

- Requirements Management Process

- Risk Management Process

- Configuration Management Process

- Technical Data/ Information Management Process

- Interface Management Process

- Quality Assurance Process

5) SYSTEMS ENGINEERING TECHNICAL REVIEWS (SETR)

Objectives:

- Explain the purpose and types of technical reviews in Systems Engineering.

- Discover technical review timelines and the importance of milestones in a System/ Product life cycle.Understand the criteria and processes for conducting effective technical reviews.

- Develop strategies for addressing issues and recommendations identified during reviews.

- Integrate technical reviews into the overall Systems Engineering process.

Course Outline:

- Overview of Milestones and Technical Reviews in a System/ Product Life cycle

- Timeline of Technical Reviews in a System/ Product Life cycle

- Different types of Technical Reviews and their importance

- Alternative Systems Review (ASR)

- System Requirements Review (SRR)

- System Functional review (SFR)

- Preliminary Design Review (PDR)

- Critical Design Review (CDR)

- System Verification Review (SVR)/ Functional Configuration Audit (FCA)

- Technology Readiness Review (TRR)

- Production Readiness Review (PRR)

- Physical Configuration Audit (PCA)

5) PRACTICAL SYSTEMS ENGINEERING AND TAILORING

Objectives:

- Tailor Systems Engineering processes to project requirements and constraints.

- Analyze real-world case studies to identify successful practices and lessons learned.

- Develop strategies for overcoming common challenges in Systems Engineering projects.

- Evaluate the effectiveness of tailoring in achieving project objectives.

- Conduct test exercises to reinforce learning and develop problem-solving skills.

Course Outline:

- Considerations for Tailoring

- Systems Engineering Methodologies & Considerations

- Types of Systems to consider

- Tailoring processes for Systems Engineering

- Application of Systems Engineering in Practical Field

- Specialty Engineering Principles

- Competency of a System Engineer

- Discovering Real-World scenarios where Systems Engineering failed

- Future of Systems Engineering