February 11, 2022 @ 8:00 am – February 13, 2022 @ 12:30 pm CET

Cost: USD760.00

GDS Engineering R&D, Inc. is an official member of the RTCA Organization.

RTCA-DO-160G Online Training, FAA/EASA Equipment Test Requirements. This training is an important step for testing and certifying your products in accordance with the FAA/EASA test requirements.

2.5 Days, Hands-on, “Online” or “Onsite” Training Class. Led by live, two instructors.

Training Schedule and Execution Type

- Training Type: International / Online

- Satus: Seats are avaiable now.

- Online training using ZOOM.

- Led by a live, U.S. based instructor (Dr Ismail Cicek) (PDF) (Download PDF)

- A usual 2.5 days of training schedule is as follows:

-

- 1st Day: 09:00 – 13:00

- 2nd Day: 09:00 – 17:00 (Lunch Break between 12:30 and 13:30)

- 3rd Day: 09:00 – 17:00 (Lunch Break between 12:30 and 13:30)

- Time zone: Central Daylight Time (US CDT, UTC-5)

-

- Ending time may vary+/-30 minutes depending on the length of the discussions.

- Course Material: English

- Comm. Language: English

- Material: Registration includes all presentations and additional material (English) shared before the class.

- Attandance: The link for online class is distributed to registered trainees upon registration.

- Attendees will receive a Training Certificate.

- Training includes knowledge check quizzes, a competition type fun way or learning.

Click to read detail information about this training:

https://www.globaldynamicsystems.com/systems-engineering-training-courses/training-on-rtca-do-160g-testing/

Dowload the PDF File: RTCA-DO-160G Training Description.PDF

Here is a Summary Information:

International Training with a focus on the test standard document

“RTCA-DO-160G Environmental Conditions

and Test Procedures for Airborne Equipment

© 2010, RTCA, Inc.”

This training is an important step for

testing and certifying your products in accordance with the FAA/EASA test requirements.

- A good understanding of product testing in view of RTCA-DO-160G

- Overview of Systems Engineering, V&V, and Concepts of Operations (CONOPS) document and relations with RTCA-DO-160 testing

- Part 21 and FAA/EASA Regulations

- Test Requirement Reference

- Test Category Selections

- Test Procedures, Scheduling, Test Implementation and Review of Test Reports

- Test Sections (Environmental & EMI/EMC): All test sections are covered with detail discussions except several tests, such as Fungus Tesing and Waterproofness are discussed in summary with important aspects.

- Discussions include design issues, test failures, and recommendations

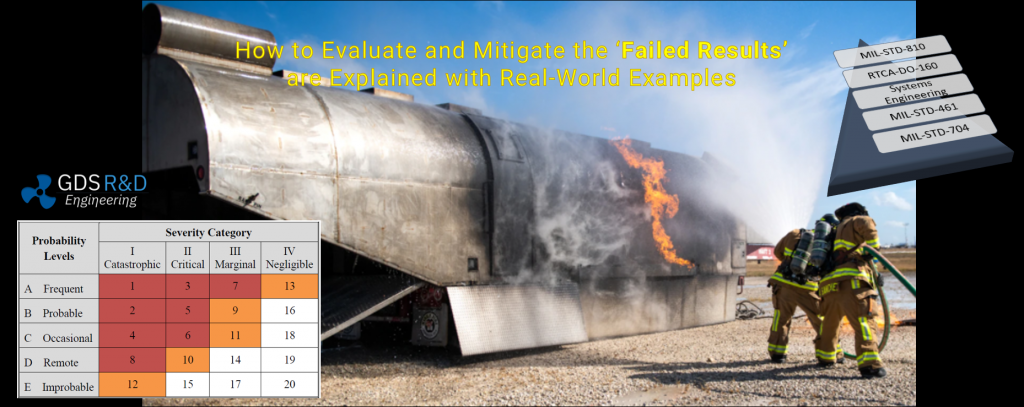

- A session with Risk Management Method includes how to resolve a test result that may not be a failure, i.e. anomalies., with a process that we recommend.

- Importance of establishing Integrated Product Team (IPT) or with another name “Test Review Team” for reviewing test plans and results and identifying the next step when issues are encountered.

- Design Recommendations are emphasized in each test section.

- Additional or alternative (standards and tests) are recommended for certain cases.

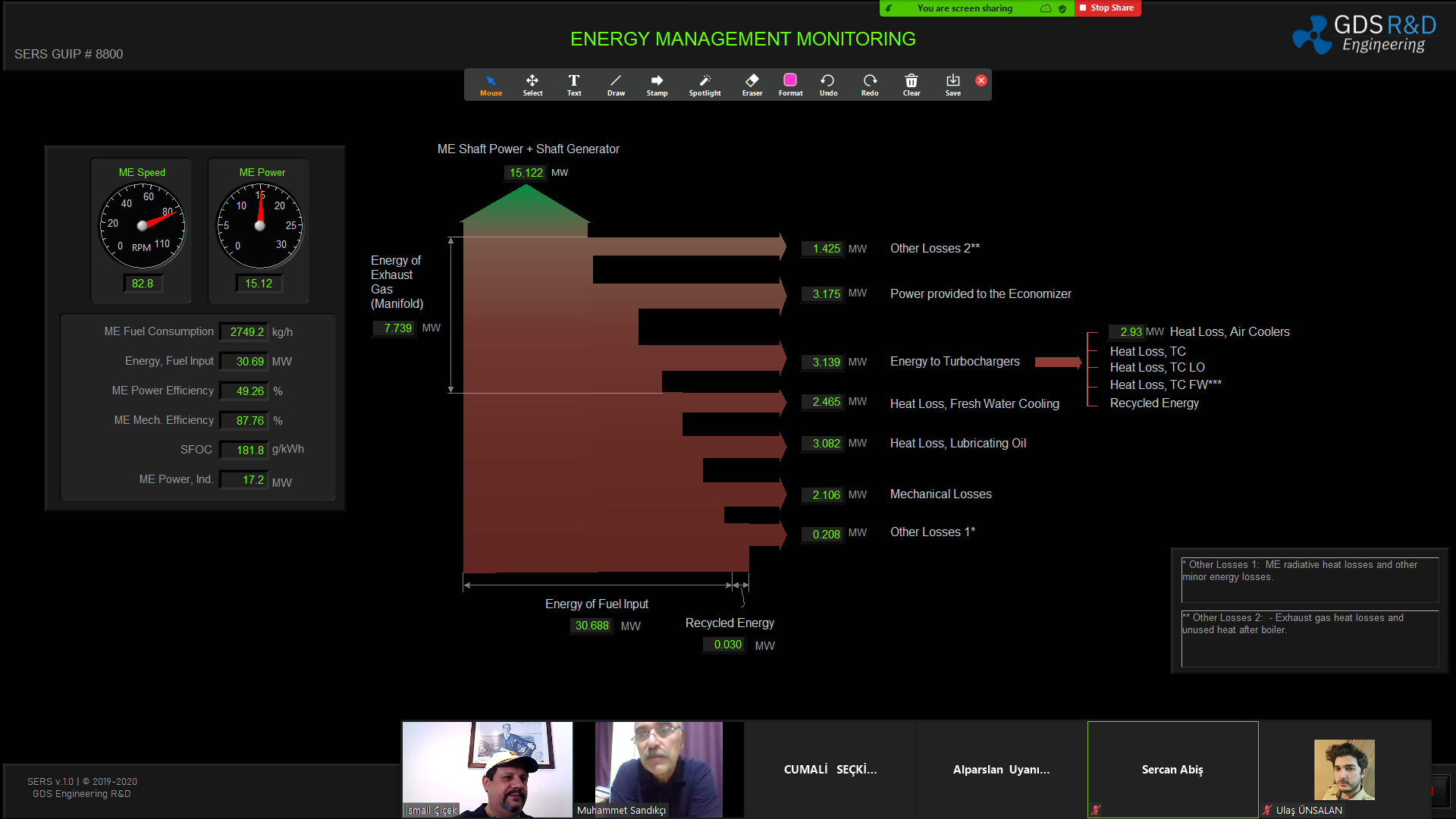

| Our Instructors share their experience and knowledge gained by working long years in the field with designing products and performing tests in accordance with such as RTCA-DO-160, MIL-STD-810, and MIL-STD-461. The slides are supported by many graphics and test videos for the efficiency and clarity of the information and each session is planned in accordance with the sections in RTCA-DO-160G. |

About the Instructors

The main instructor of the training is Dr Ismail Cicek. An Avionics Chief Engineer (EE) who is also a Certified Verification Engineer (FAA/EASA) also assists the trainings. Our experienced test personnel also becomes avialable for demonstrations and discussions.

A Certified Verification Engineer (CVE) iaw FAA/EASA and with 18 years of experience. He has worked as the avionics systems chief engineer in product development of avionics systems. He is also experienced in the product testing per environmental and EMI/EMC standards and FAA/EASA certification processes.

Our experienced personnel also support our training programs. They are actively participating in the environmental testing of products.

Dr. Ismail Cicek studied PhD in Mechanical Engineering Department at Texas Tech University in Texas, USA. He study included random vibration. He has both industrial and academic experience for over 30 years.

He gained engineering and leadership experience by working in the United States Department of Defence projects and programs as systems development engineer for 15 years. He led the development of various engineering systems for platforms including C-5, C-17, KC-10, KC-135, and C-130 E/H/J. Dr. Cicek’s experience includes unmanned aerial vehicle development where he utilized the Geographical Information Systems (GIS) and Malfunction Data Recorder Analysis Recorder System (MADARS) development for military transport aircraft.

Dr Cicek worked as the lab chief engineer for five years at the US Air Force Aeromedical Test Lab at WPAFB, OH. He received many important awards at the positions he served, due to the excellent team-work and his detail oriented and energetic personality. These included Terra Health’s Superior Client Award in 2009 and Engineering Excellence Award in 2010 as well as an appreciation letter from the US Air Force Aeronautical Systems Center (ASC), signed by the commander in charge.

Dr Cicek also established a test lab, called Marine Equipment Test Center (METC) and located at Istanbul Technical University, Tuzla Campus, for testing of equipment per military and civilian standards, such as RTCA-DO-160. Providing engineering, consultancy, and training services to many companies and organizations, Dr. Cicek has gained a great insight into the tailoring of standard test methods in accordance with military standards, guides, and handbooks as well as Life Cycle Environmental Profile LCEP) developed for the equipment under test.

Dr. Cicek also completed various product and research projects, funded in the USA, EU, and Turkey. He is currently teaching at Istanbul Technical University Maritime Faculty, Tuzla/Istanbul. He is the founding manager of the METC in Tuzla Campus of ITU. Meanwhile, he provided engineering services, consultancies, and training to many organizations for product development, engineering research studies such a algorith development, test requirements development, and test plans and executions.

Dr Cicek worked as the Principle Investigator and became a Subject Matter Expert (SME) at the US Air Force Aeromedical Test Lab (WPAFB/OH) for certifying the products to the US Air Force Platform Requirements. He also developed Joint Enroute Care Equipment Test Standard (JECETS) in close work with US Army Test Lab engineers and managers.

Read DAU Paper: “A New Process for the Acceleration Test and Evaluation of Aeromedical Equipment for U.S. Air Force Safe-To-Fly Certification”. Click to display this report.

Connect with Dr Ismail Cicek: Linkedin Page

Click here to read more about Dr Cicek’s professional studies.

Training Registration Request Form

Please fill out the following form for asking your question or with a registration request. Thank you for your interest in our training programs.

[contact-form-7 id=”229″ title=”Training Request Form 1″]