SIRE 2.0 Training

SIRE 2.0 training is designed to prepare vessel operators, crew members, and shore-side personnel for the Ship Inspection Report Programme (SIRE) 2.0, a new risk-based inspection regime introduced by the Oil Companies International Marine Forum (OCIMF).

Here's a breakdown of key aspects of SIRE 2.0 training:

Objectives:

- Understanding SIRE 2.0: Familiarize participants with the structure, methodology, and requirements of the updated inspection program. This includes the five stages of inspection (request, validation, preparation, execution, and reporting), the revised VIQ (Vessel Inspection Questionnaire), and the focus on human factors.

- Technical Knowledge: Enhance understanding of the technical aspects of vessel operations, including:

- Cargo handling and operations

- Mooring operations

- Engineering systems and maintenance

- Navigation and bridge procedures

- Safety and emergency procedures

- Environmental protection measures

- Human Factors: Develop awareness and skills related to human factors in ship operations, such as:

- Communication and teamwork

- Situational awareness

- Decision-making

- Fatigue management

- Stress management

- Leadership and management

- Compliance and Best Practices: Ensure participants are well-versed in relevant regulations and industry best practices, including:

- SOLAS (Safety of Life at Sea)

- MARPOL (International Convention for the Prevention of Pollution from Ships)

- STCW (Standards of Training, Certification and Watchkeeping for Seafarers)

- ISGOTT (International Safety Guide for Oil Tankers and Terminals

SIRE 2.0 Training Providers

Several organizations offer SIRE 2.0 training courses, including:

- SQLearn: CBT courses covering various aspects of SIRE 2.0.

- Anglo-Eastern Maritime Training Centre: A comprehensive SIRE 2.0 training course.

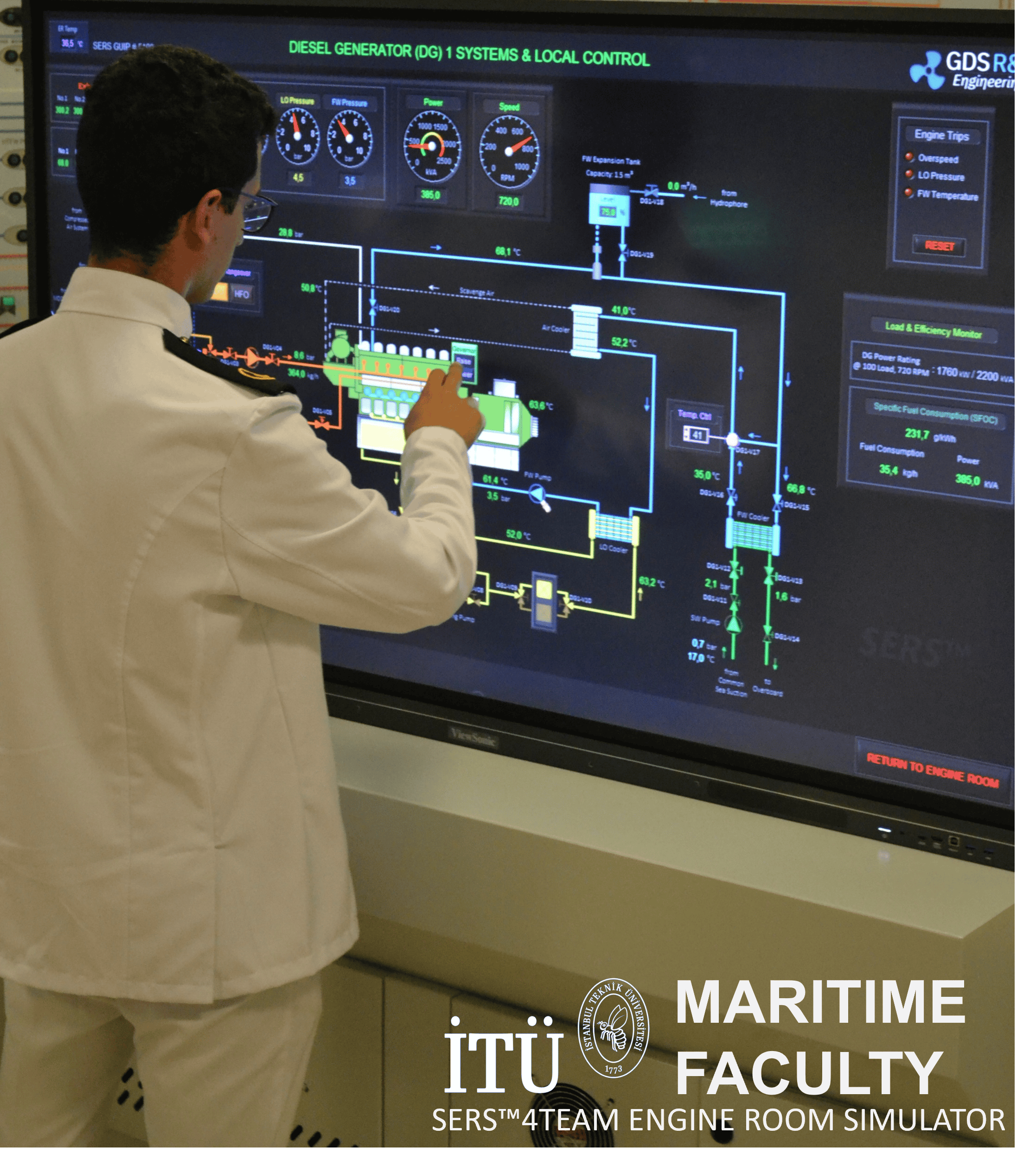

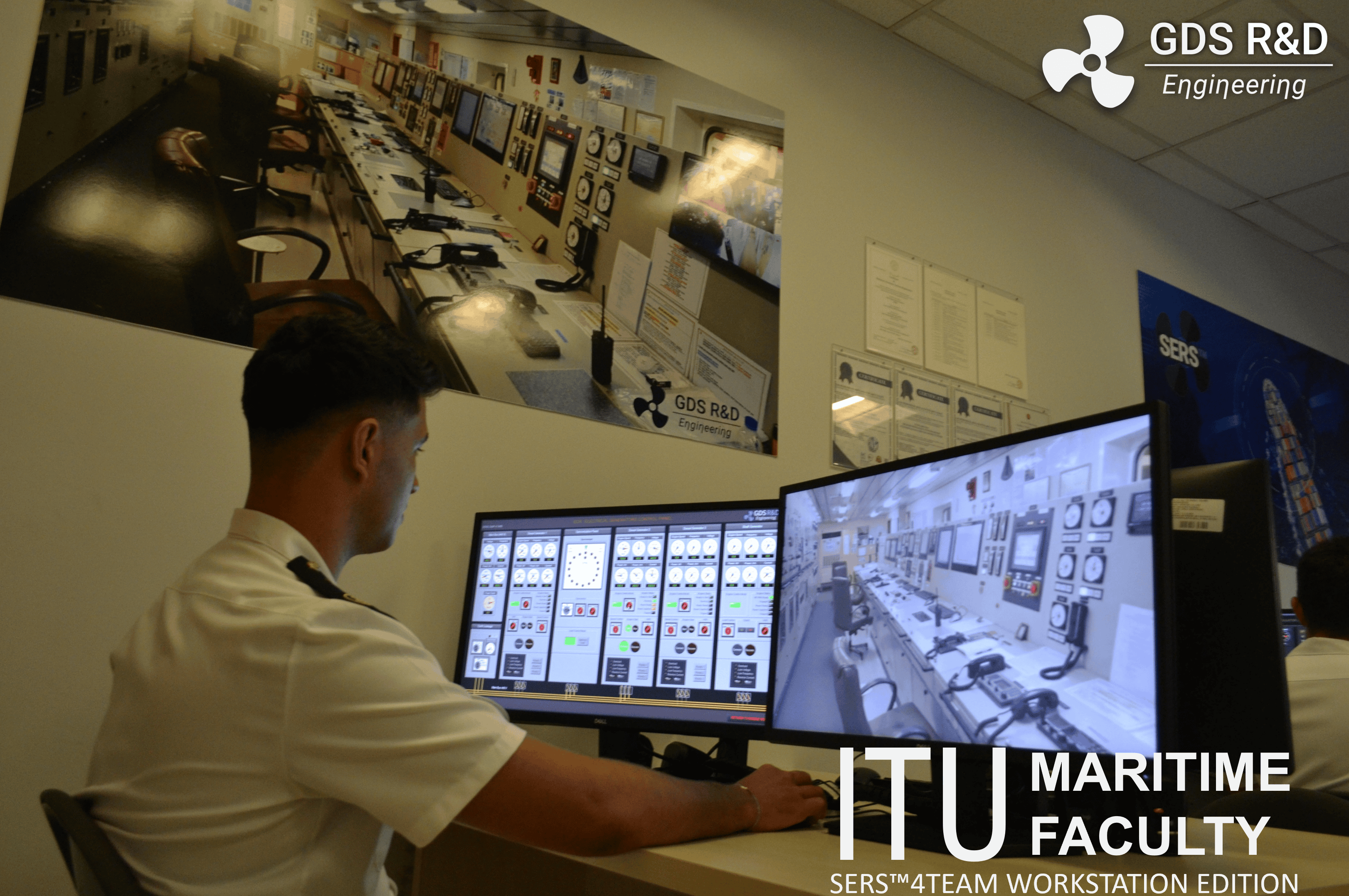

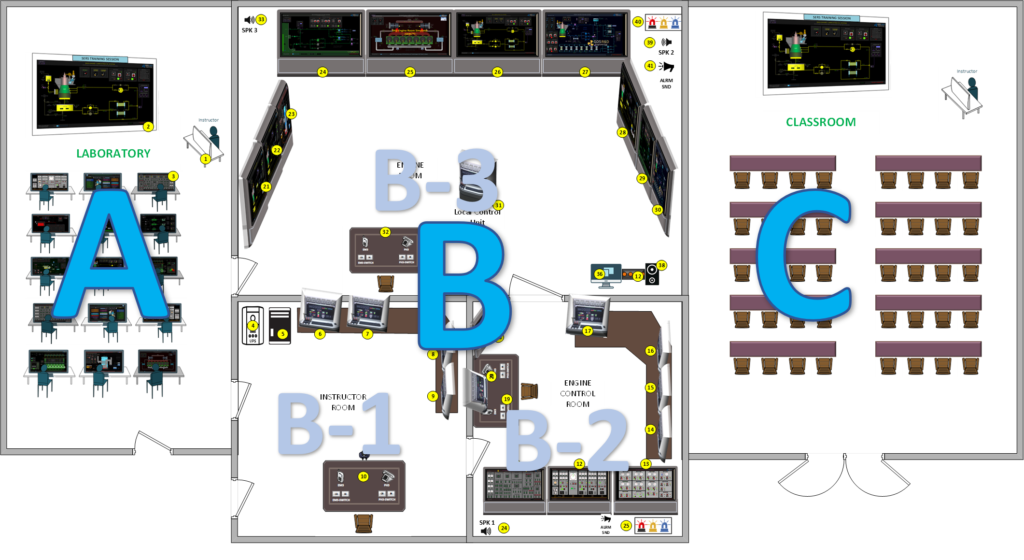

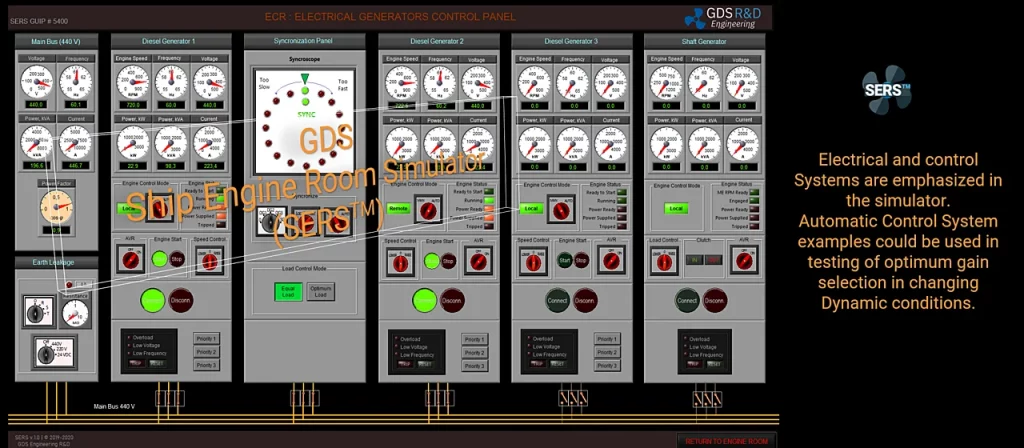

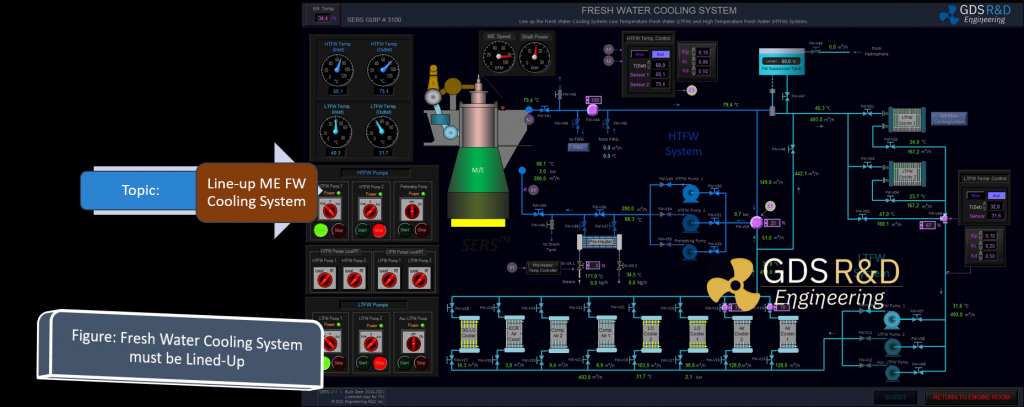

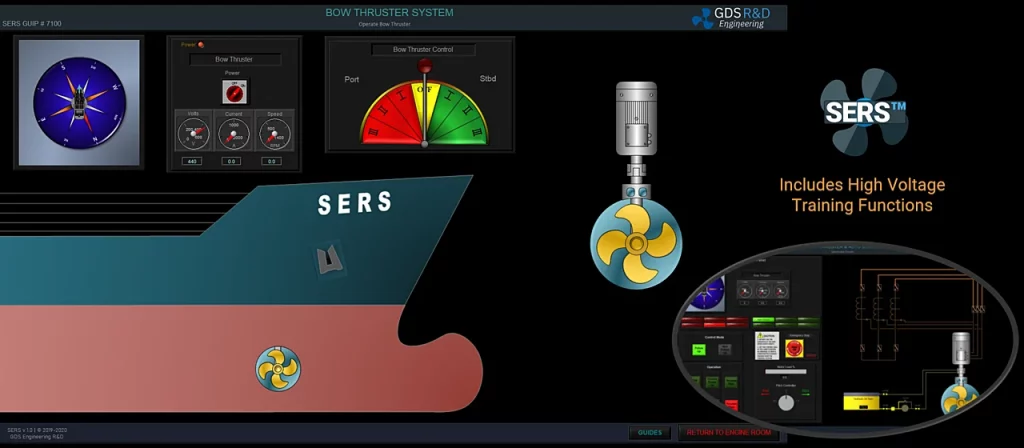

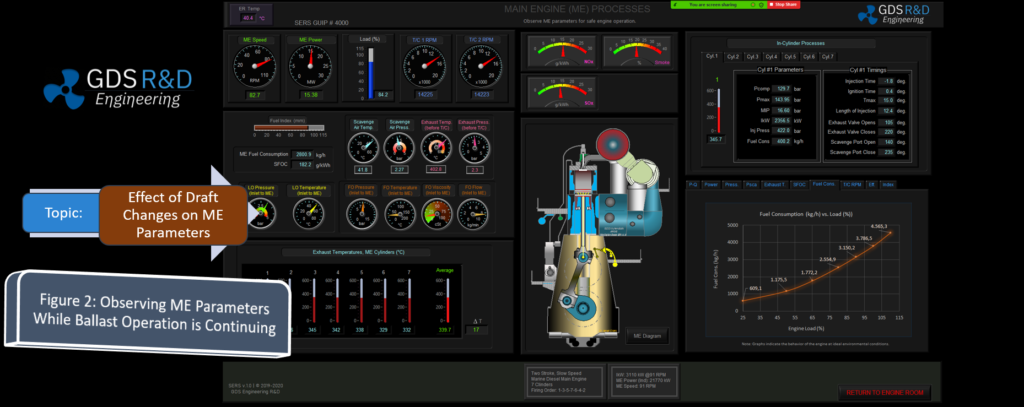

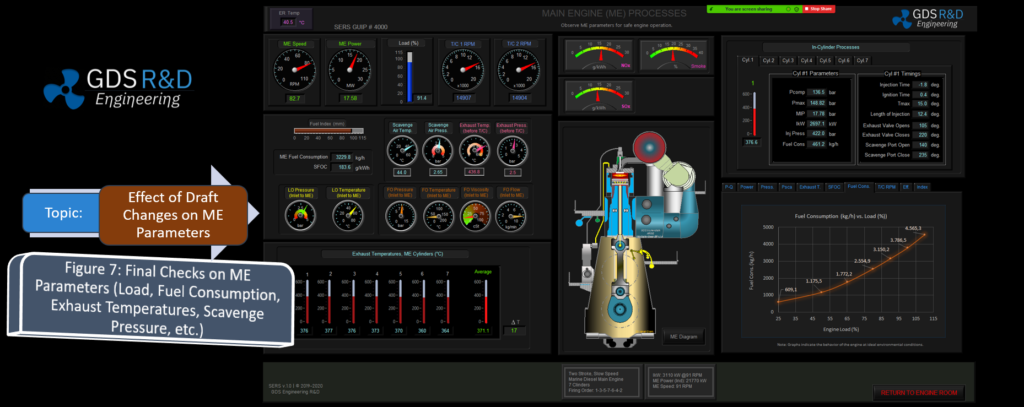

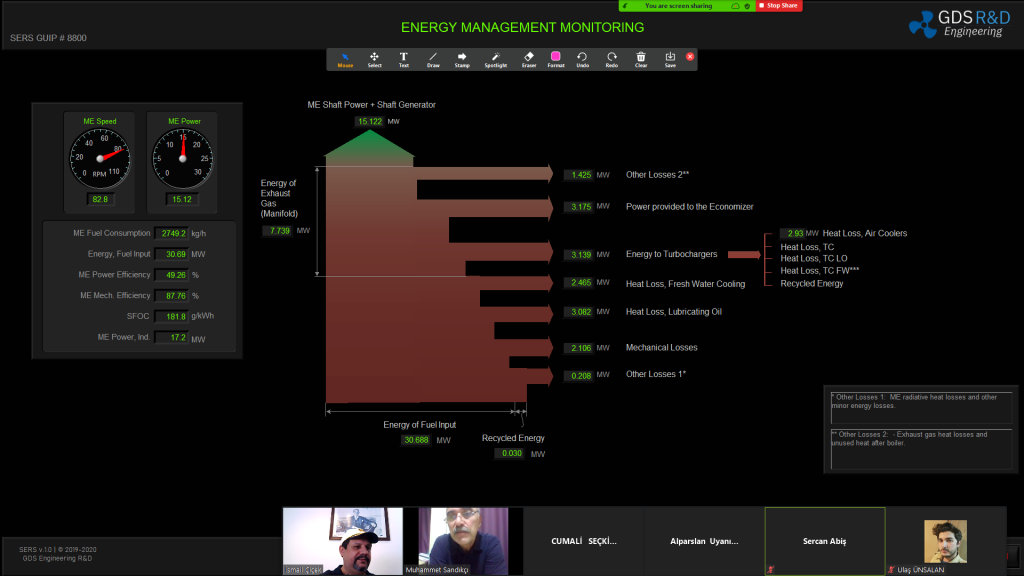

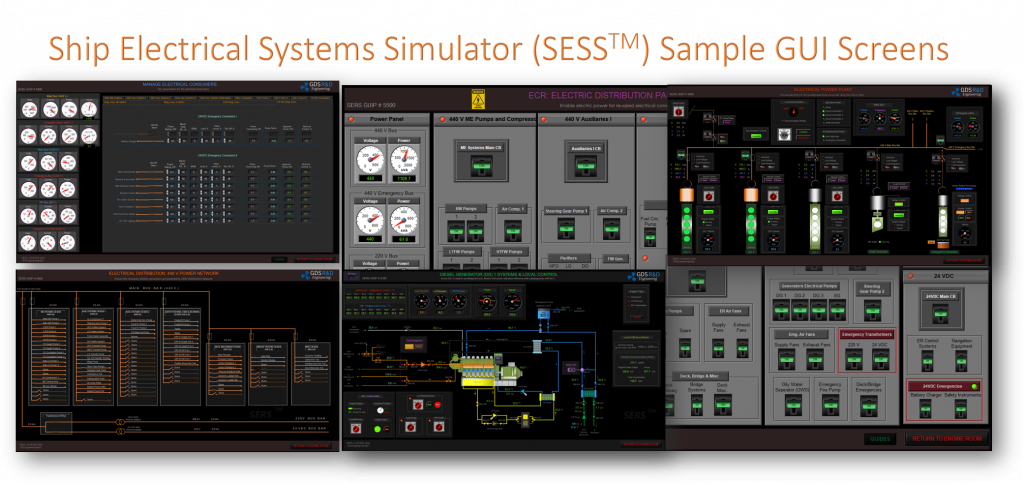

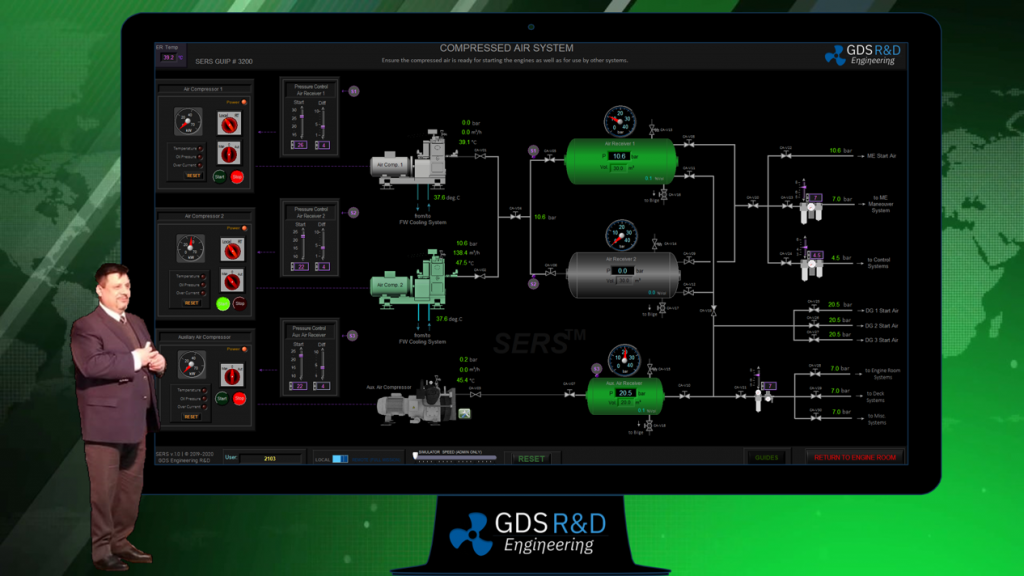

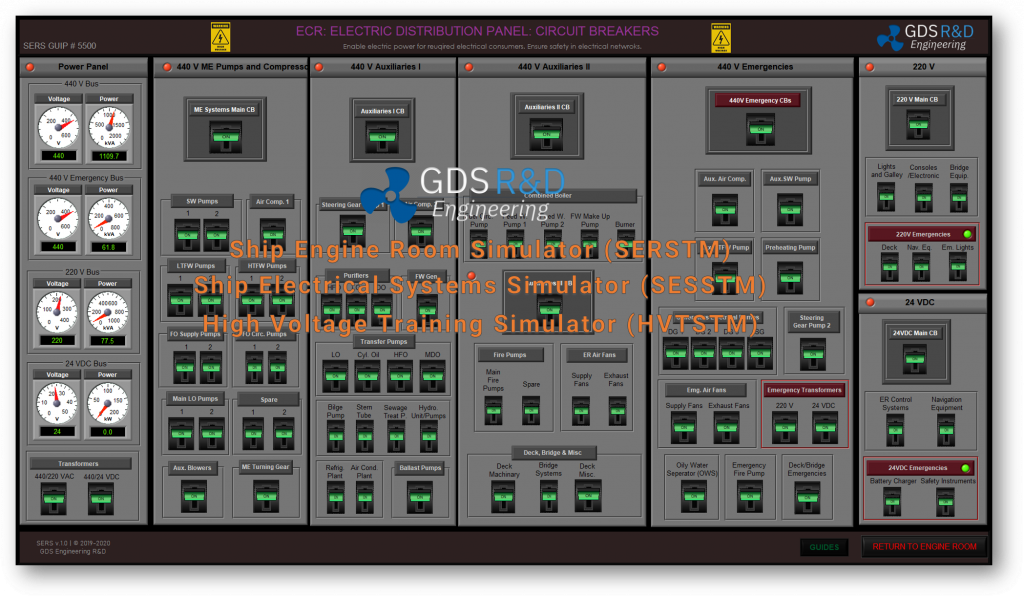

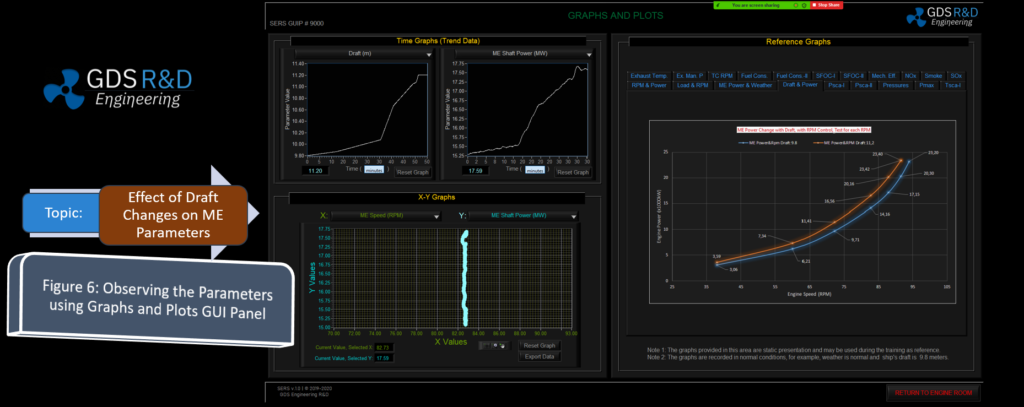

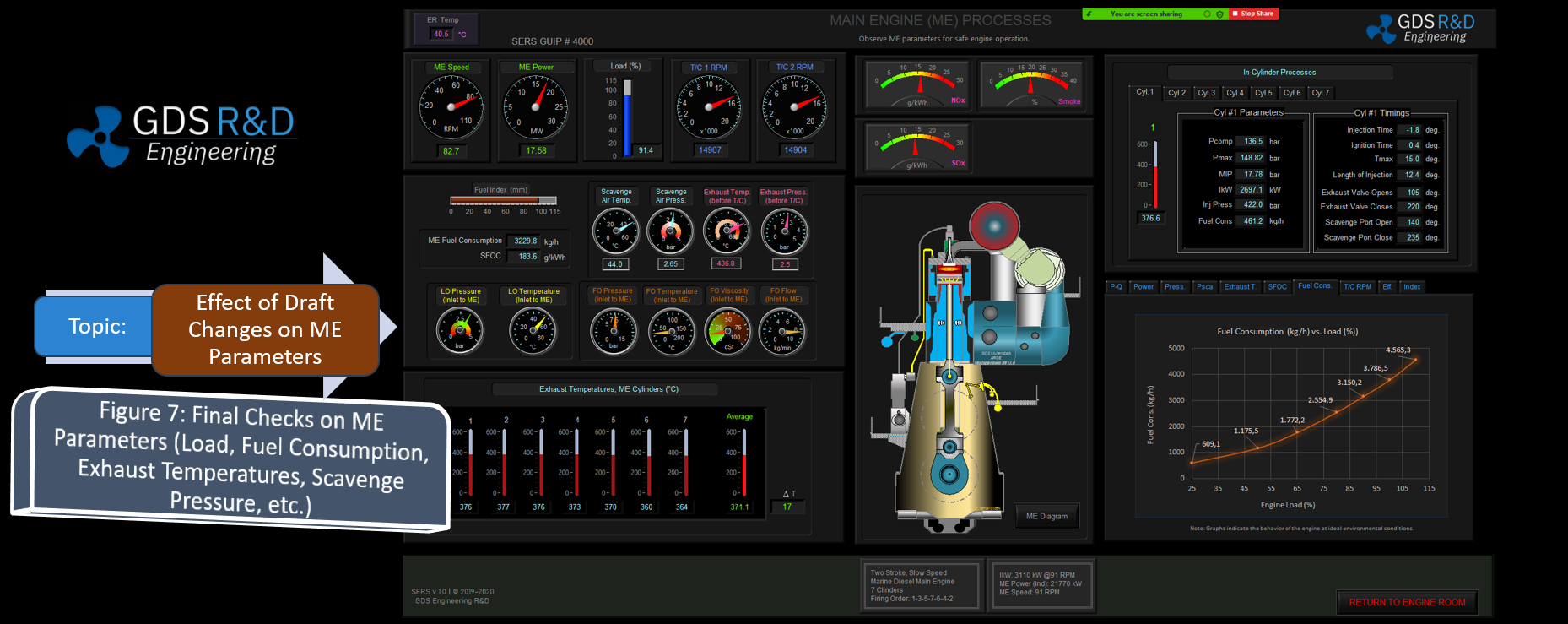

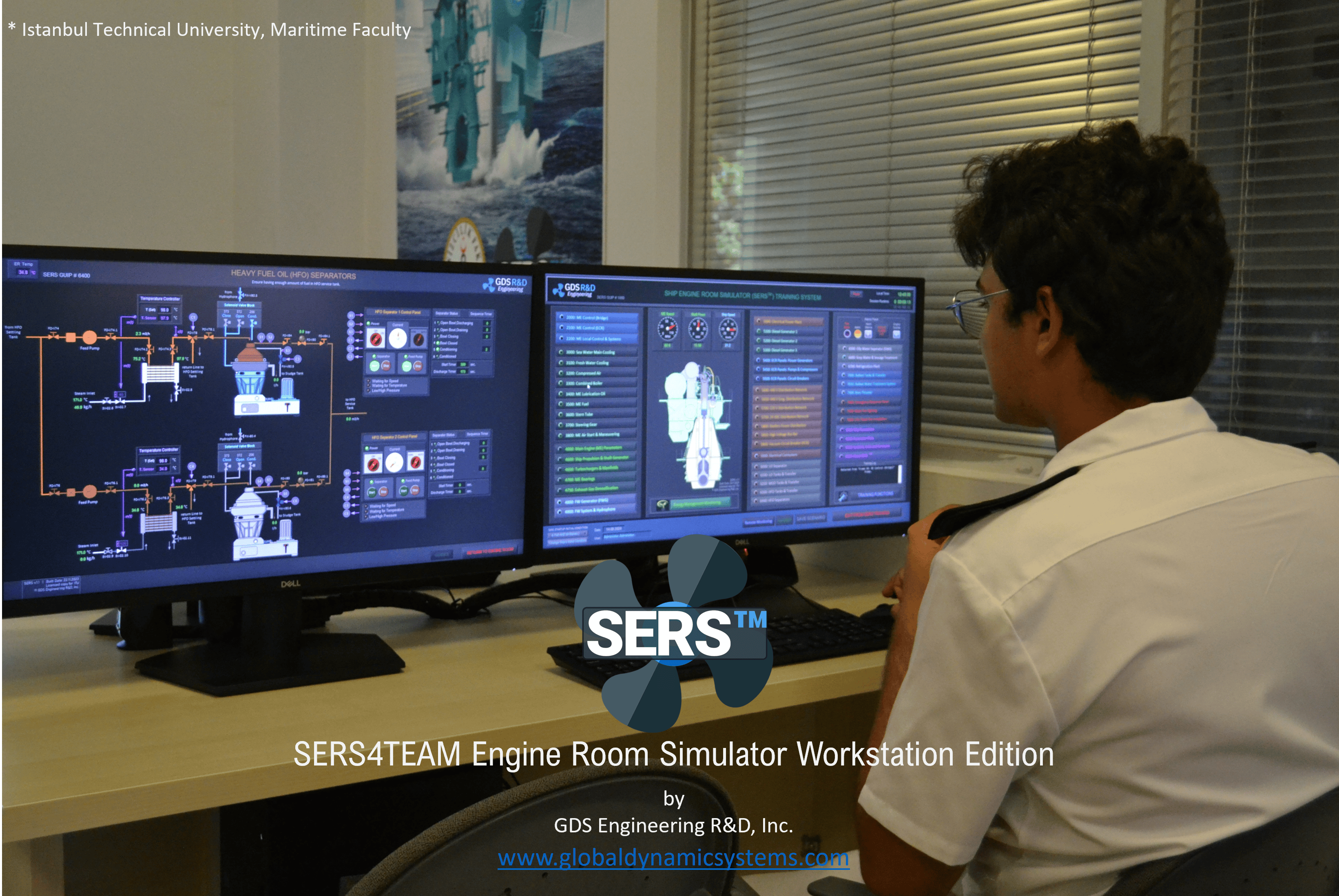

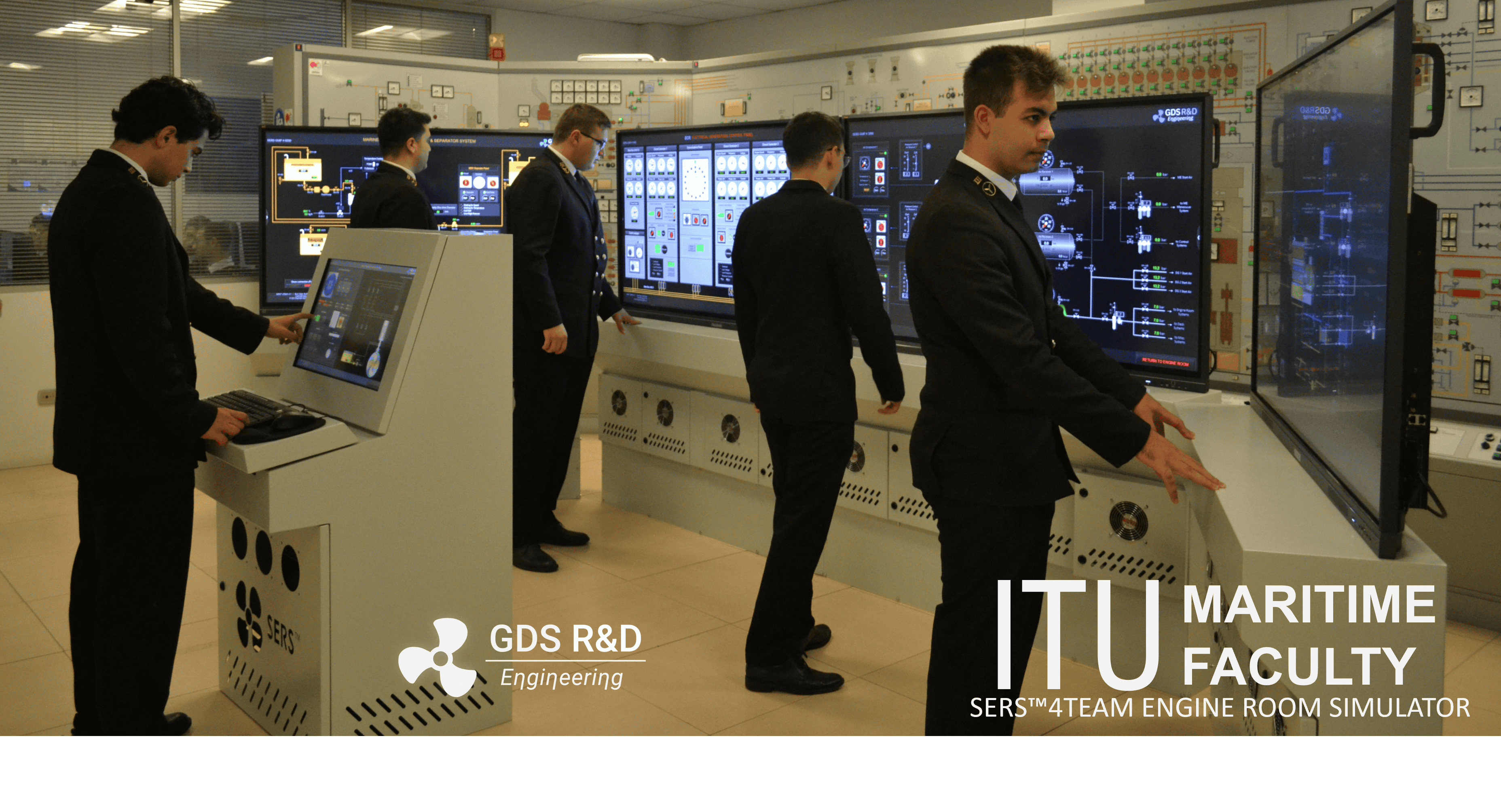

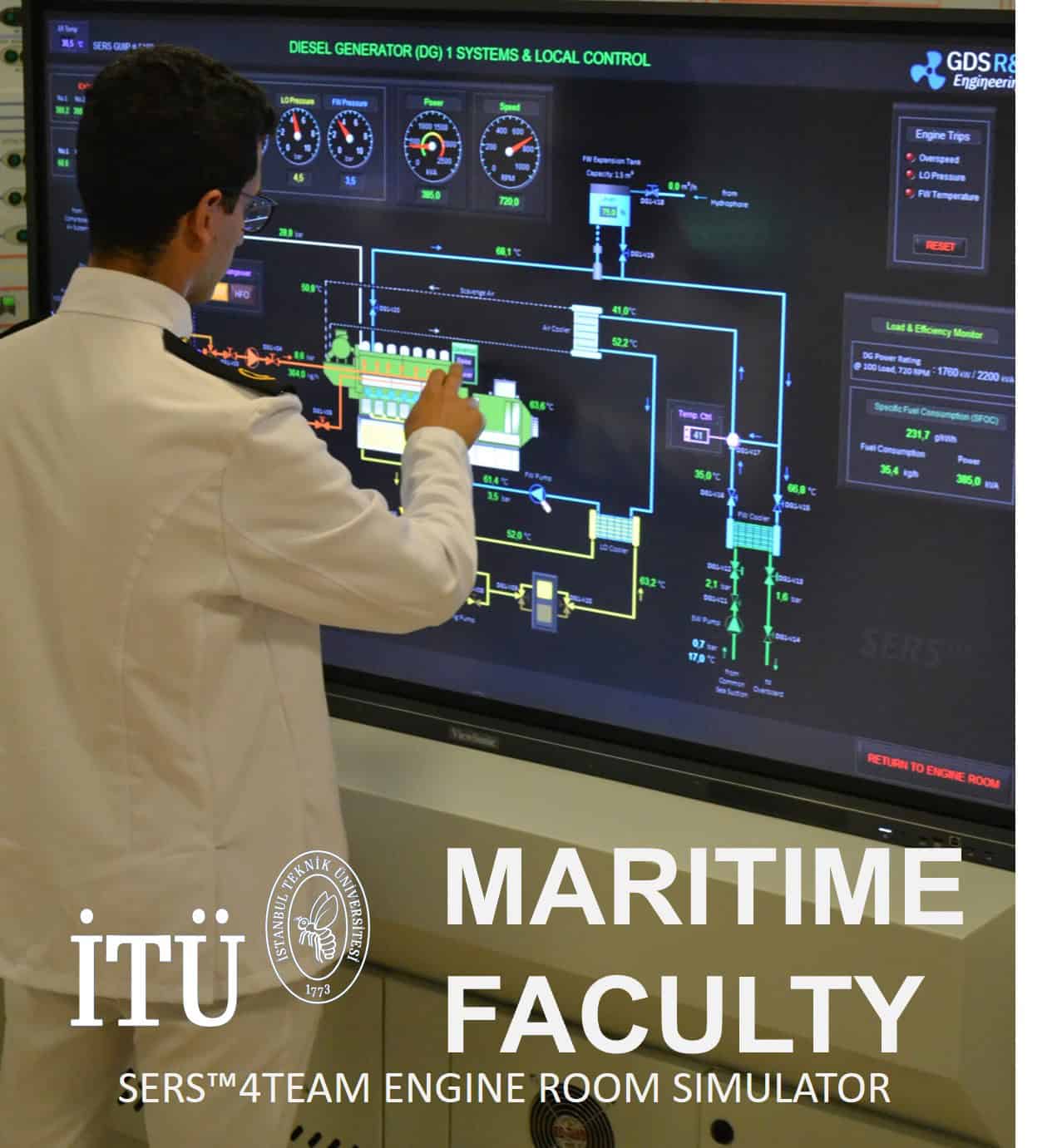

- GDS Training Institute: Developer of the Engine Room Simulator. Training offered by Istanbul Technical University Marine Engineering Department's Experts with Chief Engineering and Academic Expertise. Utilization of the GDS Ship Engine Room Simulator (SERS™) for SIRE 2.0 hands-on training. GDS & ITU Experts Team offers this training either ONLINE or FACE-to-FACE at the Istanbul Technical University Simulators Center, Tuzla, Istanbul.

- Lloyd's Register: Provides a Tanker Vetting and Inspection (SIRE 2.0) course.

- RINA: Offers a Vetting Inspections as per SIRE 2.0 course.

SIRE 2.0 Training Methods

SIRE 2.0 training can be delivered through various methods, including:

- Online Courses: Offer flexibility and convenience, allowing participants to learn at their own pace.

- Classroom Training: Provides interactive learning experiences and opportunities for group discussions and exercises.

- Simulator Training: Allows participants to practice skills and procedures in a safe and controlled environment.

- Onboard Training: Provides practical training and assessment in the actual work environment.

Benefits of the SIRE 2.0 Training using Engine Room Simulator

- Improved Safety and Environmental Performance: Enhances knowledge and skills to operate vessels safely and efficiently, minimizing risks to personnel, the environment, and cargo.

- Reduced Inspection Deficiencies: Prepares vessels and crew for SIRE inspections, reducing the likelihood of findings and non-conformities.

- Enhanced Compliance: Ensures compliance with industry standards and regulations, minimizing the risk of penalties and detentions.

- Improved Operational Efficiency: Promotes best practices and efficient operations, leading to cost savings and improved productivity.

- Increased Competitiveness: Demonstrates commitment to safety and quality, enhancing reputation and competitiveness in the industry.

By investing in SIRE 2.0 training, vessel operators and crew can ensure they are well-prepared for the new inspection regime and contribute to a safer and more sustainable maritime industry.

The Importance of SIRE 2.0 and GDS Ship Engine Room Simulator in Developing Advanced Skills for Onboard Maritime Personnel

The maritime industry has significantly pushed towards technological advancement and stricter safety and operational standards in recent years. As vessels become more sophisticated and regulations evolve, the role of well-trained onboard maritime personnel becomes increasingly essential. In this context, the SIRE 2.0 program and GDS Ship Engine Room Simulator represent pioneering tools designed to equip maritime crews with deep technical skills necessary to meet new demands and improve the safety and efficiency of maritime operations. These tools provide a more immersive and practical learning experience, allowing crew members to understand ship operations and emergency procedures better, thereby enhancing their ability to respond effectively in real-world situations.

For more reading: SIRE 2.0 Training and GDS Ship Engine Room Simulator.

Why You Should Choose GDS SERS™ in Your SIRE 2.0 Training Program?

Choosing GDS SERS (Ship Engine Room Simulator) for your SIRE 2.0 training offers several compelling advantages that can significantly enhance the effectiveness of your training program and better prepare your crew for the challenges of the new inspection regime. Here's why:

- Realistic Engine Room Environment: SERS replicates a realistic engine room environment, complete with authentic equipment, controls, and systems. This immersive experience allows trainees to interact with the machinery and systems they will encounter onboard, fostering a deeper understanding of their operation and functionality.

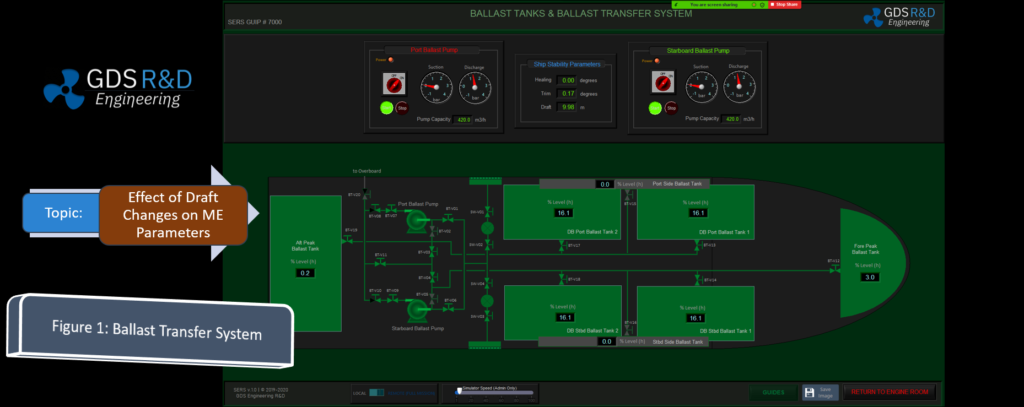

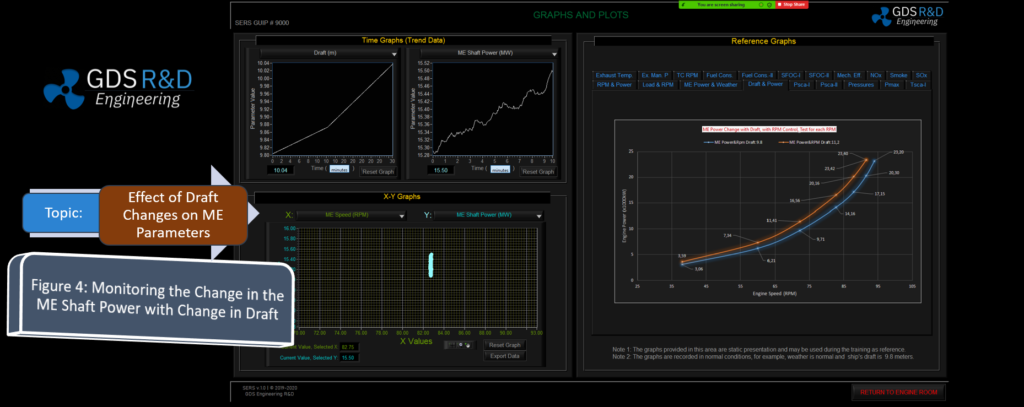

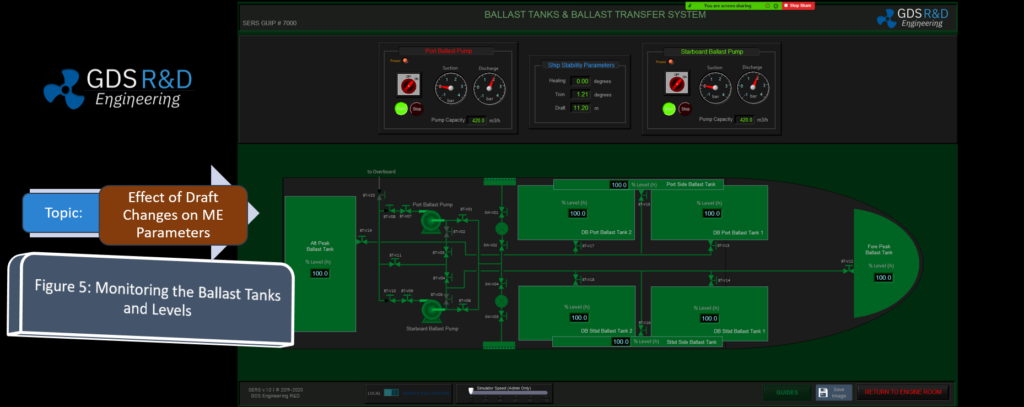

- Real-Time Simulation: SERS simulates real-time engine room operations, including dynamic responses to changes in parameters, equipment malfunctions, and emergency situations. This dynamic simulation enables trainees to develop critical thinking and problem-solving skills in a safe and controlled environment.

2. Comprehensive Training Coverage:

- Technical Skills Development: SERS facilitates the development of essential technical skills required for safe and efficient engine room operations. Trainees can practice routine maintenance, troubleshooting, and emergency procedures, gaining confidence and proficiency in their roles.

- Human Factors Integration: SERS integrates human factors principles into the training, allowing trainees to experience the impact of communication, teamwork, and decision-making in a simulated engine room environment. This helps them develop crucial non-technical skills essential for SIRE 2.0 compliance.

3. Alignment with SIRE 2.0 Requirements:

- Focus on Critical Operations: SERS training scenarios can be customized to focus on critical operations and systems emphasized in SIRE 2.0, such as cargo handling, mooring operations, and emergency response. This targeted training ensures trainees are well-prepared for the specific challenges of the new inspection regime.

- Human Factors Assessment: SERS allows for the assessment of human factors performance in a simulated environment, providing valuable insights into crew behavior and decision-making under pressure. This data can be used to identify areas for improvement and enhance crew performance in line with SIRE 2.0 expectations.

4. Cost-Effectiveness and Efficiency:

- Reduced Operational Disruption: SERS training can be conducted without disrupting actual vessel operations, minimizing downtime and associated costs. Trainees can practice and develop their skills in a simulated environment without impacting real-world operations.

- Optimized Training Delivery: SERS offers flexible training delivery options, including online and on-site training, allowing for customized training programs that meet specific needs and schedules. This flexibility optimizes training efficiency and minimizes disruption to crew schedules.

5. Continuous Improvement and Performance Monitoring:

- Performance Tracking and Analysis: SERS provides detailed performance tracking and analysis, allowing trainers to monitor trainee progress, identify areas for improvement, and provide targeted feedback. This data-driven approach ensures continuous improvement in training effectiveness and crew competency.

- Adaptability to Future Requirements: SERS can be easily updated to incorporate new technologies, regulations, and industry best practices, ensuring your training program remains relevant and aligned with evolving SIRE requirements.

By choosing GDS SERS for your SIRE 2.0 training, you invest in a comprehensive and effective training solution that enhances crew competency, improves safety performance, and ensures compliance with the latest industry standards.