Category Archives: GDS Engineering Services

Underwater radiated noise (URN) of your platform

The increase in shipping activity globally has resulted in an increased awareness of impacts on the marine environment. Effects of noise pollution, especially on marine life, have become highly prominent. Marine life is extremely sensitive to noise pollution. Due to their extreme reliance on underwater sounds for basic life functions like searching for food and mate and an absence of any mechanism to safeguard them against it, underwater noise pollution disrupts marine life (Singla, 2020). In short, marine animals depend on sound to live, making and listening to it in various ways to perform various life functions (US Bureau of Ocean Energy Management, 2014).

Noise travels much more in water, covering greater distances than it would do on land while travelling through air. Underwater sound has both pressure and particle motion components and hearing can be defined as the relative contribution of each of these sound components to auditory detection (Popper AN, 2011). Sounds radiated from ships are among the underwater noise sources. Among shipborne Underwater Radiated Noise (URN) sources are the following:

● Propeller’s rotational turn and the blades hitting to water flow lines

● Propeller’s cavitation

● Ship hull structure’s interaction water (fluid-structure interaction)

● Mechanical noises from onboard machinery

All of these noise sources are radiated to underwater from ships, especially when the ship speed is at higher rates, i.e. above 15 knots.

When a Powership is considered, out of the 4 aforementioned noises, only mechanical noise sources are of concern as there are no noises that emanate from the other three sources because the Powership is docked. Mechanical onboard noises are still of concern and therefore need to be evaluated and tested for the assessment of their potential negative effects to marine life.

At GDS Engineering R&D, Inc., we provide engineering and research services for investigating the ship underwater noise emittance and limitations.

We have established a group of engineers and academicians, called “GDS Team”, to conduct for doing an initial research on the subject. Academic staff is selected from Istanbul Technical University (ITU) Marine Equipment Test Center (METC), which is a directorate established under the ITU Rectorate. Also, GDS Engineering R&D is established in the university research park with the permission of ITU Rectorate by laws. Consisting of both academic and sectoral subject matter experts, the GDS Team hereby submits this research and evaluation paper.

Our study reflects that there has been an increase in academic and scientific studies, in the last decade, with regards to shipborne noises and their effect on marine life. Our research indicates that the International Maritime Organization (IMO) Marine Environment Protection Committee has also held a subject meeting in 2019 and published a report (IMO MEPC 74/INF.28, 2019). The IMO report indicates that there is no requirement or a strong guidance document yet published with regard to Underwater Radiated Noise (URN):

“The report provides an overview of URN issues but is not intended as a complete guide to this very complex subject.” (IMO MEPC 74/INF.28, 2019).

Similar studies show that there are no standard thresholds established and currently required as design criteria for commercial ships.

This research study focuses on the following main areas:

- Overview of previous studies on the subject.

- Evaluation of Shipborne Machinery Design and Noise Radiation using computer simulations.

- Evaluation of Karpowership design and considerations made countermeasures taken for the vibrations and noise including URN, using the state-of-the-art noise reduction and isolation techniques.

Animals will only respond directly to sounds they can detect. Marine animals depend on sound to live, making and listening to it in various ways to perform various life functions (US Bureau of Ocean Energy Management, 2014). The effect of underwater noise pollution is more painful than anything else for the animals. Most animals are alarmed by the alien sounds. The deaths can occur due to hemorrhages, changed diving pattern, migration to newer places, and damage to internal organs and an overall panic response to the foreign sounds. There is also a disruption in normal communication between marine animals as a result of underwater noise pollution. This means animals prone to noise pollution are unable to call their mates, look for food or even make a cry for help under such circumstances (Singla, 2020).

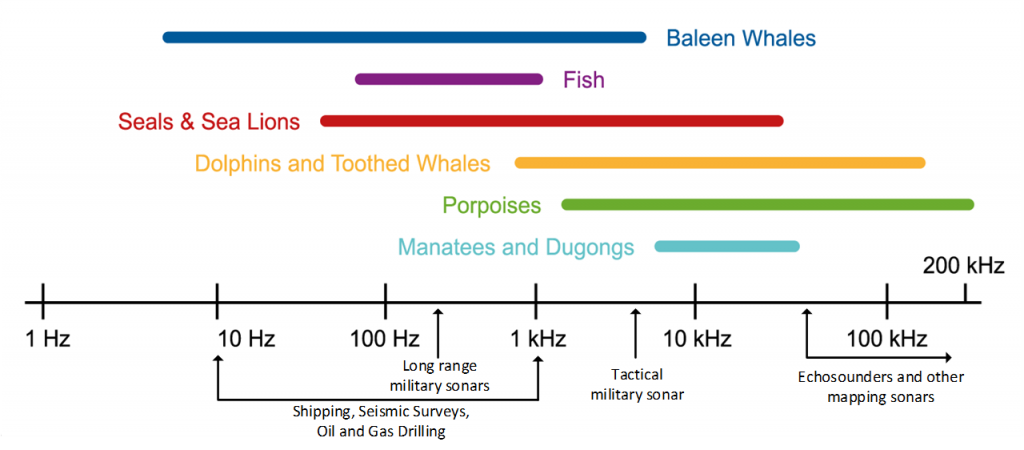

Figure 1 shows the frequency ranges produced by various marine mammal groups (US Bureau of Ocean Energy Management, 2014). The relative noise frequency bands created by various human noise sources are indicated. It also shows that all human made noises that affect various undersea life with the respective frequency ranges. Due to this fact shown with this figure along with similar studies and reports discusses in the upcoming sections, there is more attention to do research on marine mammals and industrial noises to understand how these noises affect the mammal groups.

.

Behavioral responses of marine mammals to noise are highly variable and dependent on a suite of internal and external factors. Internal factors include (Ocean Noise and Marine Mammals, 2003)

- individual hearing sensitivity, activity pattern, and motivational and behavioral state at time of exposure;

- past exposure of the animal to the noise, which may have led to habituation or sensitization;

- individual noise tolerance; and

- demographic factors such as age, sex, and presence of dependent offspring.

External factors include

- non-acoustic characteristics of the sound source, such as whether it is stationary or moving,

- environmental factors that influence sound transmission,

- habitat characteristics, such as being in a confined location, and

- location, such as proximity to a shoreline.

Many marine animals like the fish (rockfish, herring, san eel, cod, blue whiting etc.) show signs of extensive damage to their ears upon exposure to seismic air guns even up to several kilometers. Exposure to noise during embryonic stage increases sensitivity of fish to noise impact, increasing the mortality rates at time of birth and development of genetic anomalies. The migration to new areas not only affects the marine diversity balance but indirectly affects humans too. A decreased catch in many fish species like herring, cod and blue whiting especially in areas susceptible to noise pollution from ships has been noticed (Singla, 2020).

Sensitivity of various marine animals to ocean noise pollution is varying. While cetaceans like whales and dolphins may show a greater resistance, soft shelled species like mollusks, prawns, fish, etc. are much more sensitive. However, it is important to note that as many as 24 cetacean species have shown negative effects of noise pollution in the ocean. In all about 55 marine species have been noted to have suffered due to exposure to sound of varying frequencies. These include sperm whale, grey whale, mink whale, pygmy sperm whale, killer whale, sea bass, pink snapper, goldfish, cod, haddock, bluefin tuna, squid, lobster, brown shrimp etc. (Singla, 2020).

Mass stranding of giant squids in coastal areas of Spain between 2001 and 2003 showed how grave the implications of noise pollution in marine life can be. These beachings can occur merely hours after such an exercise. Dislocation or movement of marine animals to newer locations is also one of the many ocean noise pollution effects. While this may seem like a survival mechanism, studies conducted for a follow up on these animals isn’t that promising as most animals fail to acclimatize in the new environment, not to mention loss of diversity in many regions (Singla, 2020).

Sound is an extremely efficient way to propagate energy through the ocean, and marine organisms have evolved to exploit this property. Fish utilize sound for navigation and selection of habitat, mating, and communication (Bass & McKibben, 2003) (Simmonds & MacLennan, 2008).

There is a reason why the ocean is called the ‘silent world’. In this world, where sounds of their own exist, there is no room or rather any need for foreign sounds to breach the harmony of their world. Studies are being conducted to understand the effects of noise pollution on marine life in a much better way. But until a safe mechanism can be thought of which will ensure that marine animals do not continue to commit as much as mass suicide due to human errors, safety through prevention is out best shot at keeping the sanctity of this ‘silent world’ intact (Singla, 2020).

A Summary of GDS Ship Engine Room Simulator (ERS) charateristics to fit into your training program

With our product, certified by the Nippon Kaiji Kyokai (Class NK) as a Class A (Full Mission) Engine Room Simulator, our purpose is to ensure that the instructors can efficiently utilize this training environment in their Maritime Education and Training (MET) programs and that the trainees can have a productive training.

Developed by GDS Engineering R&D; our product called Ship Engine Room Simulator (SERS);

- Meets IMO STCW 2010 requirements (with Manila Amendments).

- Supports training programs using IMO Model Course 2.07 (2017 Edition).

- Certified by Class NK for meeting both IMO STCW 2010 and Model Course 2.07.

- The simulator is the digital twin model of a real ship (ref. to User Manuals for complete references and details)

- Configurable for an individual training study on a Workstation/PC

- Configurable for group studies with distributed system configuration using distributed computers and large touch-screen panels as well as association of hardware consoles and panels.

- Provides automated training reports.

- Includes high voltage training functions

- Simulates all engine room machinery and systems with over 50 Graphical User Interface (GUI) Panels.

- All systems are interfaced with all engine room parameters, any change in any parts of the systems is immediately affect the other systems, as in reality!

- Emphasizes all aspects of the electrical operations with realistic functions.

- Easy graphical user interfaces that considerably decrease the time for learning and allowing instructors to directly move on to the training objectives.

- Includes 5 User Manuals, allowing to apply the manuals to training programs directly.

- Includes Exercise Workbooks for students to come to the simulator center with their study books. When books and user manuals are incorporated, it provides a similar work studies in real ships.

- Exercise Book I is to use in the Operational Level of STCW 2010 training / competency levels. There are more than 10 example exercises are provided; already meeting the STCW objectives.

- Exercise Book II is to use in the Management Level of STCW 2010 training/ competency levels. There are more than 10 example exercises are provided; already meeting the STCW objectives.

- Engine room systems are simulated with high resolution rendered components providing easily readable GUIs on screens, which considerably decrease the learning time and moving on to the training subjects.

For more information, clisk here to read the details of the GDS ERS in our ERS product page. https://www.globaldynamicsystems.com/

or watch our YOUTUBE CHANNEL for more information with some example videos.

Learn about the Global Dynamic Systems (GDS) / GDS Engineering R&D, Inc. Products and Services

Global Dynamic Systems

(GDS Engineering R&D | GDS)

Established in 2014, GDS Engineering R&D offers products and services to the transporation industry.

The vision of GDS started earlier than 2014. Our personnel has been providing engineering services in various defense programs and projects and educational services since 1997. GDS was first estblised in San Antonio, Texas in 2008, the headquarters was then moved to Istanbul, Turkey in 2014.

Established by Dr Ismail Cicek, GDS now provides engineering services and products to the industry with a small team of engineers and managers of seven (7), academic consultants or part time subject matter experts (SMEs) of more than 10, and part-time associated students of five (5).

We provide international educational services, test support, or deliver products in various locations in the world, including the main office located in Istanbul, Turkey.

Our main product is Engine Room Simulator (ERS). All of our products are listed in summary here.

Our main services are training and consultancy services on environmental qualification test standards, such as MIL-STD-810H and RTCA-DO-160G.

MODERN IMO STCW TRAINING SIMULATORS

We develop and provide engine room simulator to the maritime schools, institutions, and companies. Our modern and effective Engine Room Simulator (ERS), certified by ClassNK in 2020, is already in use by many institutions around the world. Click here to read more about the GDS simulator products. Our simulator development story involves the collaborations with universities, industrial firms and governmental or non-governmental organizations.

Maritime Simulator Products

(SERSTM)

SERSTM is a certified, advanced, and Full Mission engine room simulator that can be used in both laboratory and distributed team environment training.

Click to read more about SERSTM.

SESSTM is a software simulation of all electrical systems in a typical engine room. It can be used as a laboratory software or in-class demonstration software.

Click to read more about SESSTM.

HVTSTM is a software, which can be used in the training of high voltage operations onboard a ship, such as Vacuum Circuit Breaker, Transformer, and high power loading to the main bus.

Click to read more about HVTSTM.

(VPLTM)

VPLTM is software, which supports the laboratory sessions of Physics I and and II experiements, which are mechanical and electrical experiments, respectively.

Click to read more about VPLTM sotware.

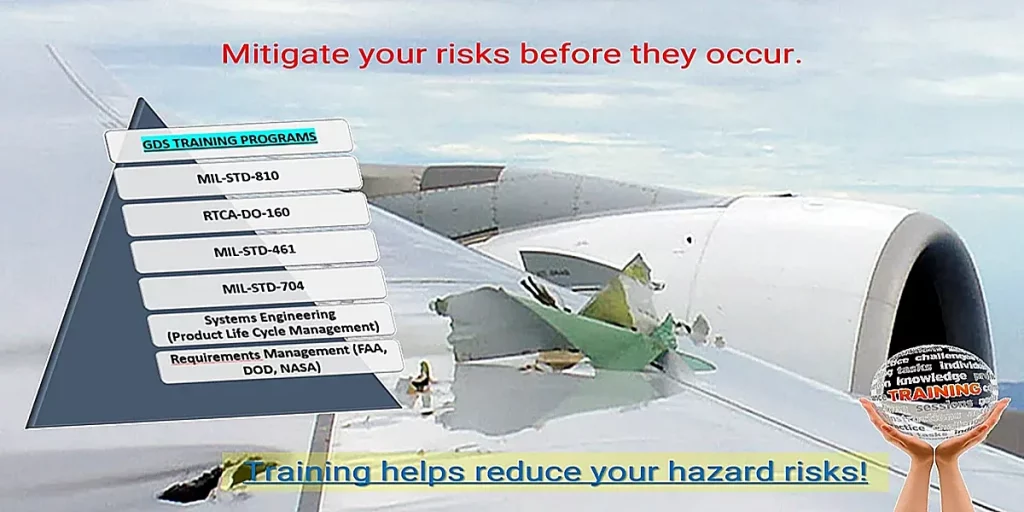

ENVIRONMENTAL TEST TRAINING FOR YOUR SUCCESS!

With years of experience in developing defence and aviations systems and environmental test experience, GDS provides training on defense, aviation, and industry test standards. Click here to read more about the details of the systems engineering and test training subjects.

Training Programs

Systems Engineering | Online or Onsite | International

Click to read more about MIL-STD-810 training program.

Click to read more about DO-160 training.

Click to read more about MIL-STD-461G training.

– MIL-STD-704F

– Req. Management

– Project Management

Click to display information about all of our training courses.

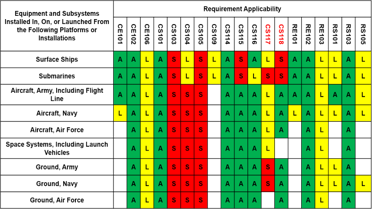

ENVIRONMENTAL TEST, ANALYSIS AND SUPPORT SERVICES

We also provide environmental testing services including the testing of your products to MIL-STD-810H, RTCA-DO-160G, and other military and industry standards. Some of which are vibrations, mechanical shock, low/high temperature, humidity, corrosion (salt spray, salt fog), and drop. We can help reduce your final issues in your product development through experience sharing, testing, or analysis.

We aim to support your business goals in the advancement of the human prosperity and healthy living.

GDS TEAM

We also prodive support to the industrial organisations in their product development or research projects by means of training, consultacies or services.

Our capabilities in desing and engineering solution projects, are, in summary:

- Online Training Courses: We provide online training courses on Systems Engineering related topics, such as MIL-STD-810H Product Testing, RTCA-DO-160G Product Testing, MIL-STD-461G EMI/EMC Testing.

- Mechanical Design: Solid modeling, parts and components desing, system design (i.e., engine parts, pipes, etc) engineering system design (cooling system, hyraulic/pneumatic systems, geabox design, etc.), surface modeling, and so on.

- Engineering Analysis: Computational Fluid Dynamics (CFD), Thermodynamics, Heat Transfer, Finite Element Analysis, Fluid-Structure Interaction, Vibration, Shock, and Sound Analysis, Impact Analysis, etc.

- System Simulations: Our firm is developing engine simulators, in which both diesel engine processes and systems and subsystems (turbocharger, air cooler, manifolds, etc.) are modeled and simulated.

- Use of the Ship Engine Room Simulator: Our engine room simulator is complete for educational use. However, it also has high level of research capabilities for use by ship operating agencies for testing and understanding their systems’ behaviors. Our simulator is basically a “twin modal” of your container type ship.

- Machine Learning: With a through study of your plant parameters, we can propose and develop useful periodic reports on how to manage your systems better with problems arising before they actually occur.

GDS Engineering has the infrastructure, knowledge, personnel, and infrastructure and has participated in or led international projects. GDS has its own Project Management System (GDS-PMS) and Quality Management System (GDS-QMS) that help produce various tools and templates for use in project or quality management, including risk-based management methods.

Our firm, consisting of in your project and company goals.

We utilize engineering software and tools depending on the Project requirements, when needed, for example: -3D CAD and CAM packages: AutoCAD, SolidWorks, Autodesk Inventor -Engineering Analysis and Optimization: ANSYS Fluent and ANSYS Packages, Autodesk Inventor -System Simulation: CATIA -GT-Power Engine Analysis and Simulation Software – SIL and HIL Simulations -LSTC LS Dyna -National Instruments LabVIEW, LabVIEW RT and NI DAQ/Control Hardware -Matlab, C/C++, and other software when needed.

We also develop our own engineering modeling and analysis programs. For example, we have our mathematical models developed for the analysis and simulation of diesel engines. This module helps testing of diesel engines and comparing the results against the simulated baseline system.

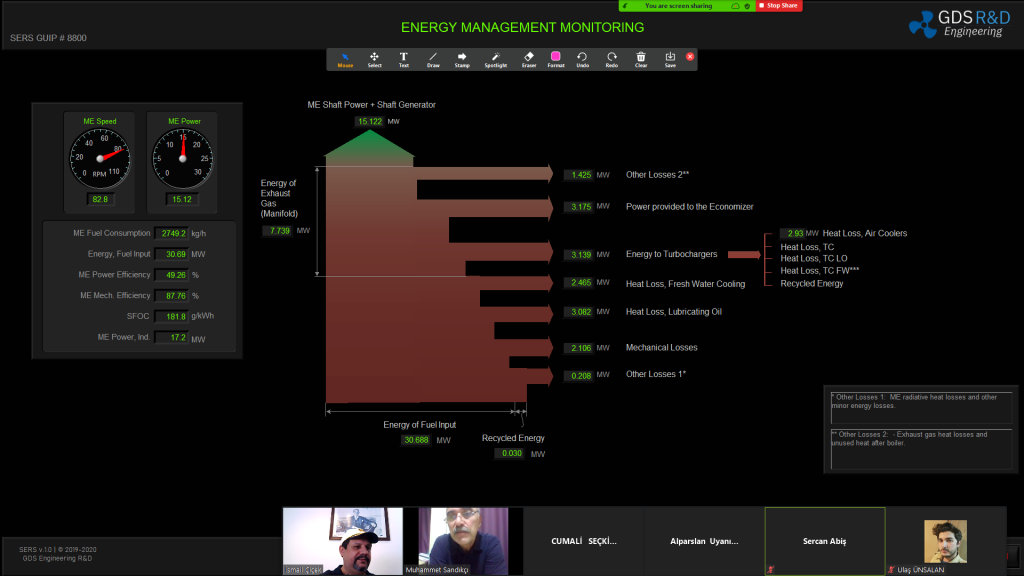

Energy Management in Marine Engineering: We understand and can model your marine engineering platform for identifying the deficiences for energy management for your cost saving.